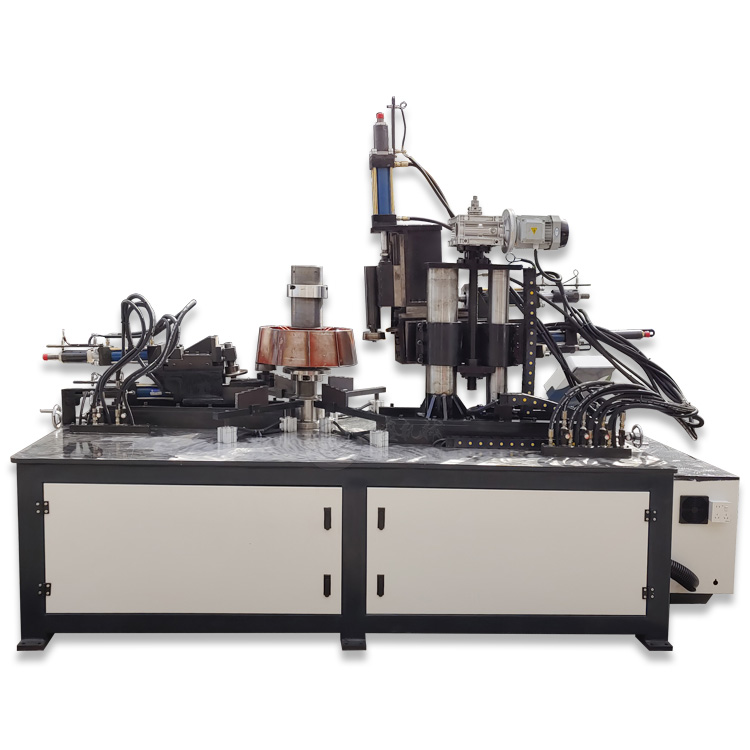

High Efficiency and Precision | Integrated Forming | Fully Automatic Hydraulic Cone Barrel Double-End Internal Flanging Machine, setting a new benchmark for industrial manufacturing!

Are you still troubled by the low efficiency, poor accuracy, and high labor costs of the flanging process at both ends of conical barrels?

Our newly launched multi-functional fully automatic hydraulic cone tube internal flanging machine completely solves your production pain points!

The core advantages of this flanging machine:

1. Double-end synchronous flanging

One-time clamping, simultaneous completion of internal flanging at both ends, efficiency increased by more than 200%, eliminating repetitive positioning errors!

2. Fully automatic hydraulic drive

Powerful and stable hydraulic system, adjustable pressure, adaptable to different material thicknesses, uniform and consistent flanging formation, no deformation, no cracks.

3. Multi-functional compatible design

Suitable for conical barrels of various tapers and diameters, quick mold change, multi-purpose machine, significantly reducing equipment investment costs.

4. Intelligent human-machine interaction

Equipped with a touch screen operating system, one-key parameter setting, simple and easy to understand operation, even novices can quickly get started.

5. Robust and durable structure

All-steel body, high-rigidity design, stable and reliable long-term operation, suitable for continuous and batch production environments.

Applicable Industries

- Chemical container manufacturing

- Metal packaging barrel production

- Environmental protection equipment processing

- Wind power tower components

- Special vehicle fuel tanks

- Various conical metal structural parts

Powerful Factory · Meticulous Manufacturing

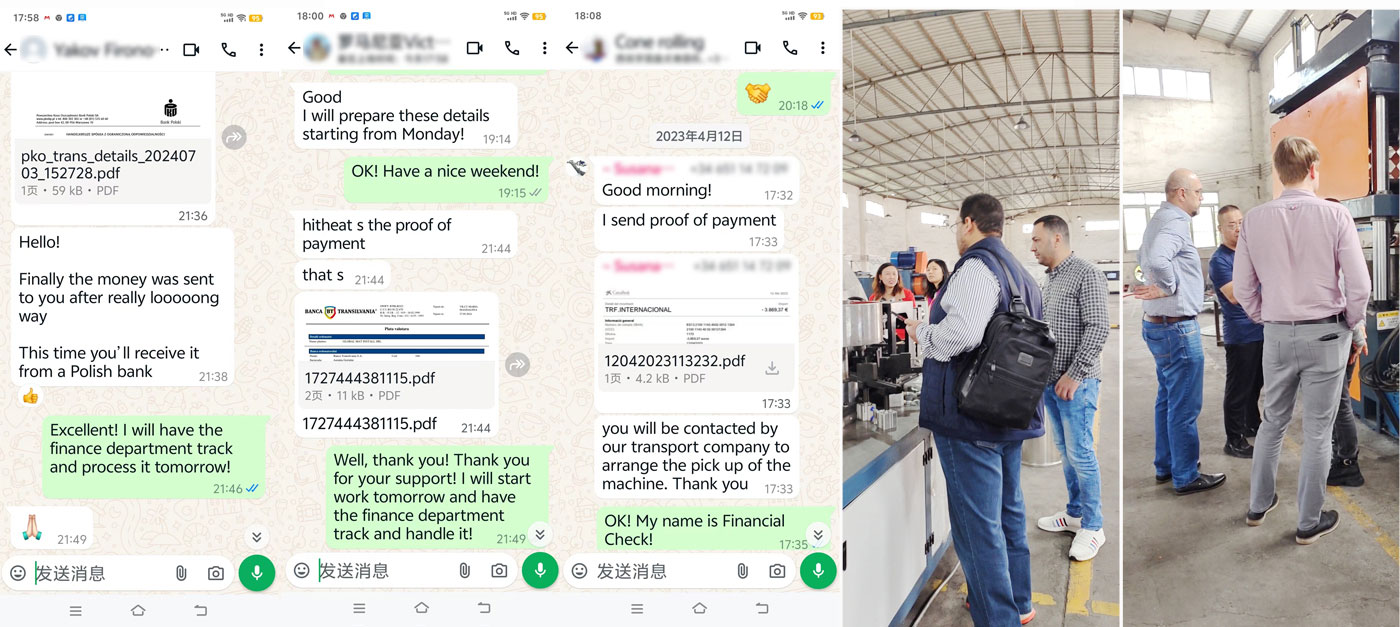

Jiangmen Zhuosheng Machinery Co., Ltd., as a leading flanging machine manufacturing factory in China, has been focusing on the research and development and manufacturing of sheet metal forming equipment for 15 years, possessing an independent R&D team and a modern production base. The company adheres to technology as the driving force and quality as the core, committed to providing customers with stable, efficient, and intelligent flanging solutions. From equipment design to factory commissioning, each flanging machine undergoes strict quality inspection and performance testing to ensure that every delivered product is a high-quality product and operates reliably.

Why choose us?

One machine, two processes, fully automatic, controllable quality. We don't just sell machines; we provide you with high-efficiency, low-cost, and standardized flanging solutions. Choosing Zhuosheng Machinery means choosing professional manufacturing, reliable quality, and comprehensive service.

Welcome to contact Jiangmen Zhuosheng Machinery for customized equipment solutions and factory videos!

Let our powerful equipment help you win at the manufacturing starting line!

1. Non-standard customization: meet personalized technical requirements.

2. Samples and drawings: professional R&D team design.

3. Flexible payment: T/T, LC, international bank.

4. Video factory inspection: can be scheduled.

5.Experienced professional sales service team.

6. Visual production process.

1. Provide circuit diagrams, maintenance manuals,full-course teaching videos and other materials required.

2. Full-time after-sales service, cooperate with customers to inspect, install and test.

3. Quick response: respond within 24 hours if there are any problems with the customers use.

| Equipment name | Multi-functional automatic hydraulic flanging machine |

| Equipment function | inner flanging of the upper and lower ends of the conical cylinder |

| Processing diameter | 200-800mm |

| Material thickness | carbon steel 0.8-3mm, stainless steel 0.8-1.5mm |

| Flanging width | not exceeding 25 millimeters(For stainless steel materials less than 15mm) |

| Workpiece height | The finished product height should be within 300mm |

| Power supply | AC380V, three-phase four-wire, 50HZ |

| Total power | approximately 7.5 kilowatts |

| Equipment weight | approximately 3000 kilograms |

| Drive mode | hydraulic |

| Control mode | PLC + touch screen |

| Operation mode | manual/automatic |

| Equipment dimensions | 3400*1500*2300mm (length * width * height) |

We are grateful for your support and trust along the way. We are honored by your cooperation every time, and we will live up to your trust and provide you with a more excellent experience.

We can also help you with all your equipment packaging needs. Whether you need split packaging, certified materials or general packaging advice, our team of experts can help you. We understand that every business is different, so we tailor our services to your needs. Our goal is to make your life easier by meeting all your packaging needs so that you can focus on running your business.

As a professional mechanical equipment manufacturer, our company is a private technology innovation enterprise integrating independent research and development, design and manufacturing, installation and commissioning, and training.

Our R&D team has 10 people, whose members cover multiple professional fields such as mechanical engineering, electronic information, and materials science, and have the ability to deal with different technical problems.

Our equipment is widely used in aerospace, energy, ventilation,hardware and furniture, tableware, medicine, electricity, packaging,construction,automobile and other industries and fields.

Q: When shipping, what kind of packing?

A: We use standard export packing.

Q: What are your delivery terms?

A: EXW, FOB, CFR, CIF.

Q: What's your delivery time?

A: Generally speaking, it takes 30 to 60 days after receiving your advance payment. The specific delivery time depends on the item and quantity of your order.

Q: Can you make it as required?

A: Yes, we can produce according to your samples or technical drawings. We can make molds and fixtures.

Q: Do you have professional engineers?

A: Yes.we have professional engineers and designers.

Q: Can you provide customzied machines?

A:Yes, we can design and manufacture according to your specific requirements.