Automatic hydraulic S-edge multifunctional flanging machine for metal cylindrical cone vacuum feeder shell

---A fully automatic solution specially designed for vacuum feeder shells

When your production line is still troubled by the flanging process of the vacuum feeder shell: Jiangmen Zhuosheng Machinery Co., Ltd., with 15 years of non-standard customization experience, has launched a revolutionary dual-head four-station fully automatic hydraulic flanging machine-specially for the pain points of flanging process!

The upper and lower hydraulic units work simultaneously to complete the flanging + S-sealing edge of the cylinder/conical barrel at one time, and the efficiency is increased by 300%

The production capacity exceeds 600 pieces in 8 hours, saying goodbye to the efficiency bottleneck of 200 pieces of traditional single machines!

Take action now to bring your vacuum feeder shell production into the era of high efficiency and intelligence!

The production capacity exceeds 600 pieces in 8 hours, saying goodbye to the efficiency bottleneck of 200 pieces of traditional single machines!

Take action now to bring your vacuum feeder shell production into the era of high efficiency and intelligence!

1. Non-standard customization: meet personalized technical requirements.

2. Samples and drawings: professional R&D team design.

3. Flexible payment: T/T, LC, international bank.

4. Video factory inspection: can be scheduled.

5.Experienced professional sales service team.

6. Visual production process.

1. Provide circuit diagrams, maintenance manuals,full-course teaching videos and other materials required.

2. Full-time after-sales service, cooperate with customers to inspect, install and test.

3. Quick response: respond within 24 hours if there are any problems with the customers use.

| item | value |

| Voltage | 380V |

| Power (kW) | 13.5 |

| machine type | Cold Forging Machine |

| weight (kg) | 3500 |

| warranty | 1 Year |

| place of origin | China Guangdong |

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | PLC, motor |

| key selling points | Easy to Operate, Automatic, Competitive Price, Multifunctional, Long Service Life, High Productivity |

| Equipment function: | Double-head flanging and pressing S-edge for cylindrical cone barrels |

| Processing workpiece diameter: | 200-1300mm |

| Material thickness: | 0.8-4mm carbon steel, 0.8-3mm stainless steel |

| Flanging width: | 20-50mm |

| Work efficiency: | 30-40 seconds/piece |

| Processing workpiece height: | 200-1300MM |

| Drive mode: | hydraulic |

| Control mode: | PLC+touch screen |

| Action mode: | manual/automatic |

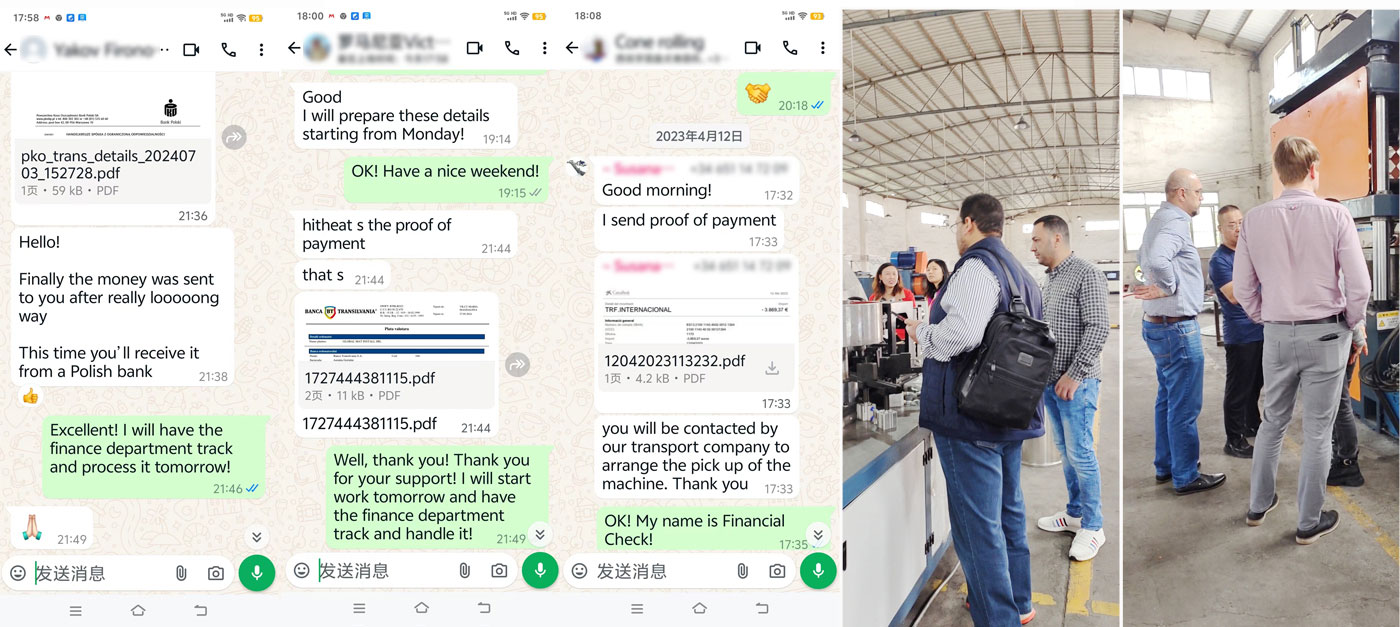

We are grateful for your support and trust along the way. We are honored by your cooperation every time, and we will live up to your trust and provide you with a more excellent experience.

We can also help you with all your equipment packaging needs. Whether you need split packaging, certified materials or general packaging advice, our team of experts can help you. We understand that every business is different, so we tailor our services to your needs. Our goal is to make your life easier by meeting all your packaging needs so that you can focus on running your business.

As a professional mechanical equipment manufacturer, our company is a private technology innovation enterprise integrating independent research and development, design and manufacturing, installation and commissioning, and training.

Our R&D team has 10 people, whose members cover multiple professional fields such as mechanical engineering, electronic information, and materials science, and have the ability to deal with different technical problems.

Our equipment is widely used in aerospace, energy, ventilation,hardware and furniture, tableware, medicine, electricity, packaging,construction,automobile and other industries and fields.