A flanging machine is a device used for processing the edges of metal sheets. It performs operations such as curling and folding the edges of metal sheets to create specific shapes and structures, thereby improving the aesthetics, strength, and sealing of the product. In industrial production, flanging machines are widely used in various fields, including machining, and are an essential piece of metalworking equipment. Through precise mechanical control and advanced processing technology, flanging machines can achieve complex edge shapes to meet the design requirements of various products.

1. High-Efficiency Production:

The Automatic Hydraulic Cylinder Cone Flanging Machine is a fully automated solution designed specifically for vacuum feeder housings. The upper and lower hydraulic units operate simultaneously, completing both the curling and S-shaped sealing of cylindrical/conical barrels in a single operation, increasing efficiency by 300%. Its production capacity can exceed 600 pieces in 8 hours, breaking the efficiency bottleneck of 200 pieces per traditional single machine. Hydraulically driven, with an operating voltage of 380V and a power output of 13.5kW, it weighs 3,500kg and is a cold forging machine. Its operating principle is to provide powerful power through the hydraulic system, enabling the upper and lower hydraulic units to quickly and accurately complete the curling and S-shaped sealing processes, significantly improving production efficiency and reducing production costs.

2. Versatile Processing:

This flanging machine features dual-head curling and S-shaped press functions, and can process both cylindrical and conical barrels. The machine can process workpiece diameters ranging from 200-1300mm, material thicknesses from 0.8-4mm for carbon steel and 0.8-3mm for stainless steel, and hemming widths from 20-50mm. This versatility allows it to meet the processing needs of workpieces of varying sizes and materials, enabling a single machine for multiple uses and improving equipment utilization and flexibility. Whether large or small, the machine accurately completes hemming and S-shaped hemming, ensuring consistent and stable processing quality.

3. Ease of Operation:

The flanging machine utilizes a PLC + touchscreen control system for simple and convenient operation. Users can intuitively set and adjust processing parameters via the touchscreen, enabling quick operation without extensive training. It features two operating modes: manual and automatic, allowing for flexible switching based on production needs. In automatic mode, the machine automatically completes hemming and S-shaped hemming according to pre-set procedures, significantly reducing manual intervention and improving production efficiency and consistent processing quality. Furthermore, the machine's user-friendly interface and clear workflow facilitate quick mastery and operation.

4. Competitive Pricing:

Despite its advanced technology and versatility, the Automatic Hydraulic Cylinder Cone Flanging Machine boasts a highly competitive price in the market. This is due to ZHUOSHENG's over a decade of expertise in customizing non-standard machinery and its effective cost control. While ensuring quality and performance, ZHUOSHENG has reduced manufacturing costs through optimized design, rational material selection, and efficient production management, providing customers with a more cost-effective product.

5. Long Service Life:

The core components of this flanging machine utilize high-quality PLCs and motors, ensuring stability and reliability. These core components undergo rigorous quality inspections and testing, ensuring they maintain excellent performance over extended periods of operation and minimizing the likelihood of failure. Furthermore, the machine's overall structural design is rationally designed and constructed from high-strength materials, offering excellent wear and fatigue resistance. With proper use and maintenance, the machine's service life can reach several years or even longer, ensuring long-term, stable production and reducing replacement costs.

6. High Productivity:

The flanging machine boasts exceptionally high efficiency, with a processing time of 30-40 seconds per piece. This means the machine can process more workpieces per unit time, significantly improving production efficiency. Its workpiece height range is 200-1300mm, meeting the processing needs of workpieces of varying heights. This high productivity makes the machine excellent in large-scale production, enabling rapid fulfillment of customer orders and enhancing the company's market competitiveness.

7. Strict Quality Control:

ZHUOSHENG provides comprehensive quality assurance for its Cylinder Cone Flanging Machine. Before shipment, the machine undergoes rigorous video inspection to ensure that every component meets quality standards. ZHUOSHENG also provides a test report, giving customers a clearer understanding of the machine's performance and quality. This rigorous quality control system, from raw material procurement and production to finished product inspection, ensures high quality and performance.

8. Comprehensive After-Sales Service:

The Flanging Machine comes with a one-year warranty, ensuring peace of mind for customers. During the warranty period, ZHUOSHENG will provide free repair or replacement services for any non-human faults. In addition, ZHUOSHENG also has a professional after-sales service team that can respond to customers' inquiries and problem feedback in a timely manner and provide customers with a full range of technical support and after-sales services.

| item | value |

| Voltage | 380V |

| Power (kW) | 13.5 |

| machine type | Cold Forging Machine |

| weight (kg) | 3500 |

| warranty | 1 Year |

| place of origin | China Guangdong |

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | PLC, motor |

| key selling points | Easy to Operate, Automatic, Competitive Price, Multifunctional, Long Service Life, High Productivity |

| Equipment function: | Double-head flanging and pressing S-edge for cylindrical cone barrels |

| Processing workpiece diameter: | 200-1300mm |

| Material thickness: | 0.8-4mm carbon steel, 0.8-3mm stainless steel |

| Flanging width: | 20-50mm |

| Work efficiency: | 30-40 seconds/piece |

| Processing workpiece height: | 200-1300MM |

| Drive mode: | hydraulic |

| Control mode: | PLC+touch screen |

| Action mode: | manual/automatic |

1. Non-standard customization: meet personalized technical requirements.

2. Samples and drawings: professional R&D team design.

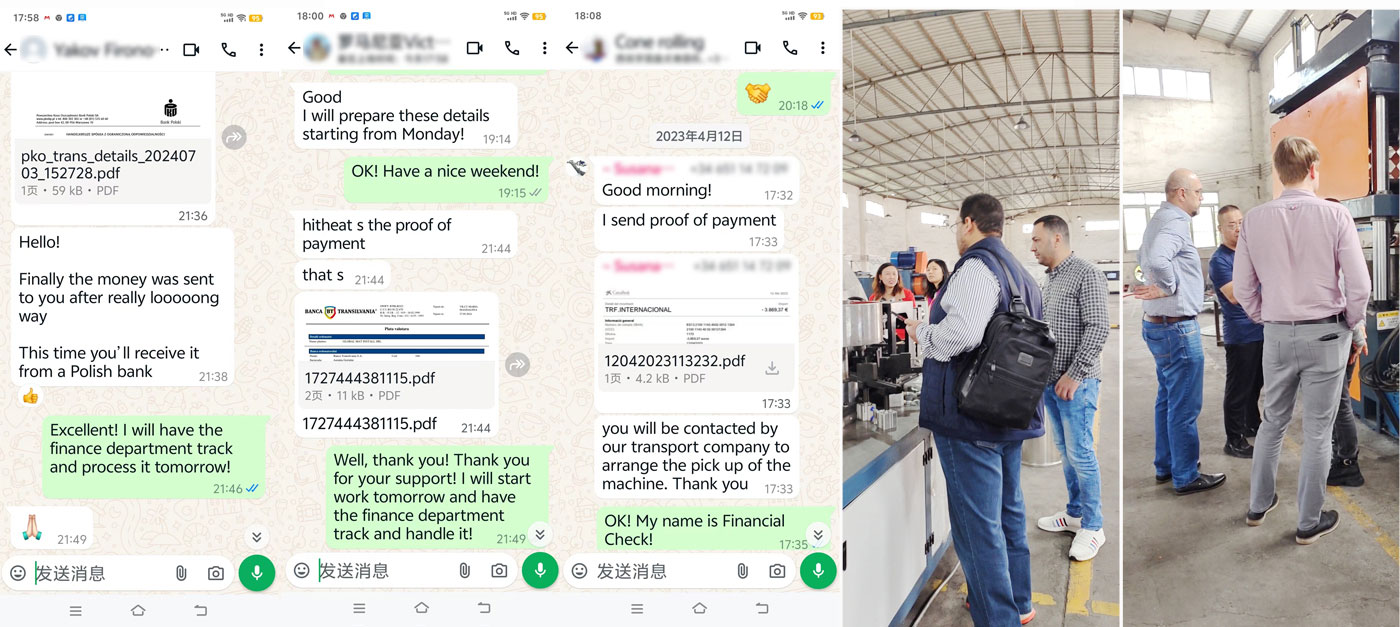

3. Flexible payment: T/T, LC, international bank.

4. Video factory inspection: can be scheduled.

5.Experienced professional sales service team.

6. Visual production process.

1. Provide circuit diagrams, maintenance manuals,full-course teaching videos and other materials required.

2. Full-time after-sales service, cooperate with customers to inspect, install and test.

3. Quick response: respond within 24 hours if there are any problems with the customers use.

1. Vacuum Feeder Housing Processing:

The Automatic Hydraulic Cylinder Cone Flanging Machine is specifically designed for vacuum feeder housings, efficiently completing flange and S-shaped edge processing. Vacuum feeder housings typically require excellent sealing and strength. This machine ensures sealing performance and structural stability through precise flange and S-shaped edge processing. During production, the machine quickly and accurately completes processing tasks, improving production efficiency and reducing production costs, providing a reliable processing solution for vacuum feeder manufacturing.

2. Automotive Parts Manufacturing:

In the automotive manufacturing sector, flange machines are widely used in the processing of automotive parts. For example, parts such as hoods, doors, and body frames require flange processing to enhance component strength and aesthetics. This machine meets the high precision and efficiency requirements of automotive parts manufacturing, ensuring component quality and performance through precise flange and S-shaped edge processing. Its high production capacity and stable processing quality provide strong support for automotive parts manufacturers, improving their production efficiency and market competitiveness.

3. Home Appliance Manufacturing:

The housings and components of home appliances such as washing machines, refrigerators, and air conditioners also require hemming. The Automatic Hydraulic Cylinder Cone Flanging Machine can efficiently and precisely hem and slant edges on these appliance housings and components, enhancing their aesthetics and durability. Its versatility and high production capacity meet the stringent quality and efficiency requirements of home appliance production, providing ideal processing equipment for home appliance manufacturers, helping them improve product quality and efficiency.

4. Aerospace Component Manufacturing:

The aerospace industry places extremely high demands on component processing precision and quality. Flanging machines play a vital role in aerospace component manufacturing, enabling high-precision hemming of aircraft engine components, wing structures, and more. The machine's high-precision machining capabilities and stable performance ensure that the quality and performance of aerospace components meet stringent standards. Its advanced technology and reliable performance provide high-quality processing solutions for aerospace component manufacturing, ensuring the safety and reliability of aerospace products.

5. Machining Industry:

In the machining industry, flanging machines are widely used to process various mechanical parts. For example, mechanical transmission components and hydraulic cylinder housings require hemming to improve component strength and sealing. The Automatic Hydraulic Cylinder Cone Flanging Machine meets the diverse demands of the machining industry for processing quality and efficiency. Through precise hemming and S-shaped processing, it ensures component quality and performance. Its versatility and high production capacity provide machining companies with efficient processing equipment, improving their production efficiency and economic benefits.

6. Metal Product Processing:

Flanging machines are also used in the processing of metal products such as metal containers and metal pipes. This equipment can be used to hem the edges of metal containers, improving their sealing and aesthetics. It can also be used to hem metal pipes, enhancing joint strength and sealing performance. The Automatic Hydraulic Cylinder Cone Flanging Machine's versatility and high-efficiency production capacity can meet the metal processing industry's high requirements for processing quality and production efficiency, providing metal manufacturing companies with high-quality processing equipment and promoting the development of the metal processing industry.

We are grateful for your support and trust along the way. We are honored by your cooperation every time, and we will live up to your trust and provide you with a more excellent experience.

We can also help you with all your equipment packaging needs. Whether you need split packaging, certified materials or general packaging advice, our team of experts can help you. We understand that every business is different, so we tailor our services to your needs. Our goal is to make your life easier by meeting all your packaging needs so that you can focus on running your business.

As a professional mechanical equipment manufacturer, our company is a private technology innovation enterprise integrating independent research and development, design and manufacturing, installation and commissioning, and training.

Our R&D team has 10 people, whose members cover multiple professional fields such as mechanical engineering, electronic information, and materials science, and have the ability to deal with different technical problems.

Our equipment is widely used in aerospace, energy, ventilation,hardware and furniture, tableware, medicine, electricity, packaging,construction,automobile and other industries and fields.