Multifunctional automatic hydraulic cone barrel conical flanging machine

Large cone barrel flanging machine Conical flanging machine features:

Ⅰ. Large cone barrel flanging machine Conical flanging machine has wide applicability, suitable for S-shaped flanging and curling of oblique flow fans, Shakron shells, powder vacuum feeders and agricultural machinery shells. It is widely used for flanging and punching of various conical cylinders and forming of sheet metal parts such as fans, vibrating screens, and pressure vessels. The equipment has fast flanging speed, stable flanging quality, high punching accuracy, smooth flanging mouth, and can be punched, folded, and curled after flanging, etc., which can be customized according to customer requirements.

This equipment can be equipped with the following functions according to customer needs: curling, trimming, punching, flaring, etc.

This large cone flanging machine The cone flanging machine can also be used with our factory's automatic plate rolling machine and automatic cone rolling machine. The machine rolls without straight edges. At the same time, it cooperates with our factory and automatic straight seam welding machine for welding, and the product quality is more stable.

There are two types of punching hole spacing accuracy according to customer needs: precision hole spacing accuracy within 1MM, ordinary type accuracy within 3MM

R edge rolling is only suitable for workpieces with material thickness within 2.5MM

External round edge repair is only suitable for product material thickness greater than 2.5MM.

Ⅱ. Large cone flanging machine The cone flanging machine is simple to operate. Ordinary workers only need simple training to start working. The machine only needs one person to operate, just put the workpiece up and down.

Ⅲ.This machine can also flanging and punching the upper and lower cone heads of various cones, and press the edges and ribs according to customer drawings.

Ⅳ.Product after-sales service:

1.Product quality warranty period: Except for consumables, the warranty period of this machine equipment is 12 months after acceptance.

2.Repair:

① If the equipment has quality problems during the warranty period, the seller will repair it free of charge unconditionally; if the equipment is damaged due to improper operation by the buyer, the seller will charge the cost of the accessories and travel expenses during the repair.

② After the warranty period, if the equipment fails, the seller will charge the corresponding service fee in addition to the cost of the accessories and travel expenses.

| Specifications | Flanging diameter (mm) | Material thickness (iron plate) | Material lifting method | Flanging method |

| 700 type | 150-700 | 0.8-2.5 mm | Cylinder | Front and rear wheel type |

| 1300 type | 200-1300 | 1-3mm | Cylinder | Front and rear wheel type |

| 1600 type | 400-1600 | 1-6mm | Cylinder/hydraulic | Clamping and flipping type |

| 2000 type | 400-2000 | 1-6mm | Hydraulic | Clamping and flipping type |

| 2500 type | 600-2500 | 2-8mm | Hydraulic | Clamping and flipping type |

| 3000 type | 600-3000 | 3-12mm | Hydraulic | Clamping and flipping type |

1. Non-standard customization: meet personalized technical requirements.

2. Samples and drawings: professional R&D team design.

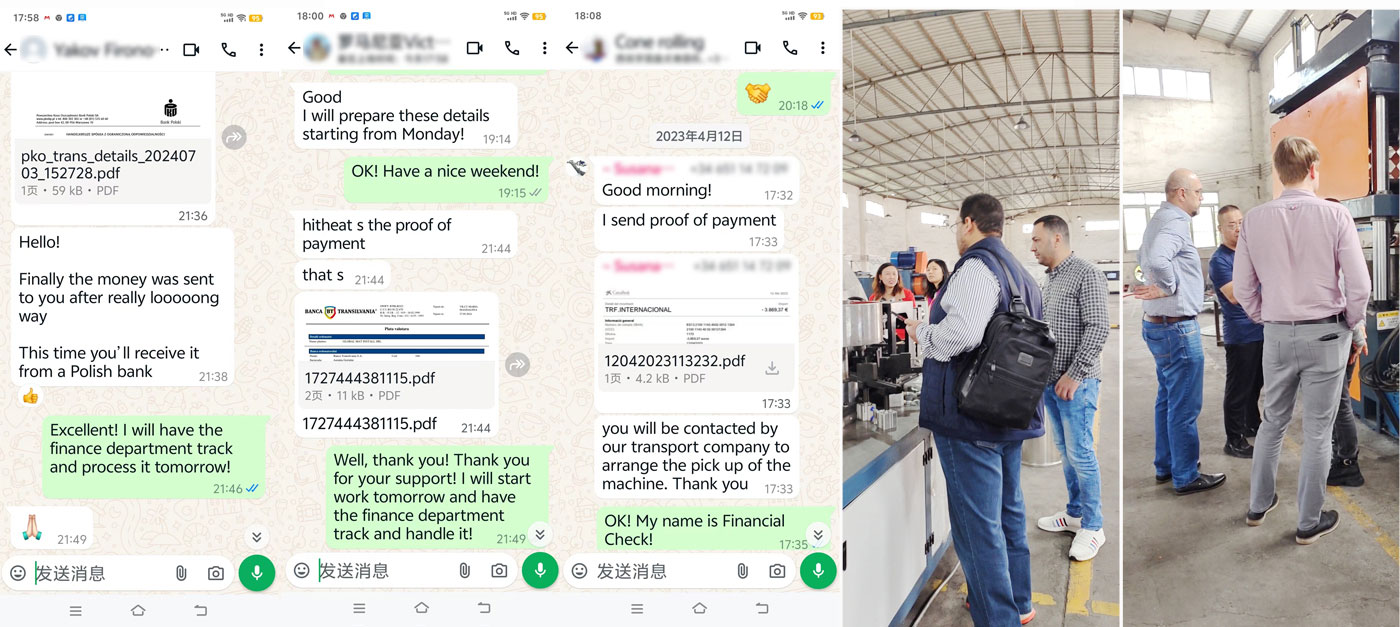

3. Flexible payment: T/T, LC, international bank.

4. Video factory inspection: can be scheduled.

5.Experienced professional sales service team.

6. Visual production process.

1. Provide circuit diagrams, maintenance manuals,full-course teaching videos and other materials required.

2. Full-time after-sales service, cooperate with customers to inspect, install and test.

3. Quick response: respond within 24 hours if there are any problems with the customers use.

We are grateful for your support and trust along the way. We are honored by your cooperation every time, and we will live up to your trust and provide you with a more excellent experience.

We can also help you with all your equipment packaging needs. Whether you need split packaging, certified materials or general packaging advice, our team of experts can help you. We understand that every business is different, so we tailor our services to your needs. Our goal is to make your life easier by meeting all your packaging needs so that you can focus on running your business.

As a professional mechanical equipment manufacturer, our company is a private technology innovation enterprise integrating independent research and development, design and manufacturing, installation and commissioning, and training.

Our R&D team has 10 people, whose members cover multiple professional fields such as mechanical engineering, electronic information, and materials science, and have the ability to deal with different technical problems.

Our equipment is widely used in aerospace, energy, ventilation,hardware and furniture, tableware, medicine, electricity, packaging,construction,automobile and other industries and fields.