Metal Corrugated Pipe Expansion Joint Compensator Forming Machine

As one of China's leading manufacturers of customized non-standard mechanical equipment, Jiangmen Zhuosheng Machinery Co., Ltd.'s 350-1500 series metal corrugated pipe expansion joint compensator rib expansion machines provide professional solutions for displacement compensation, vibration reduction, noise reduction, and flexible connections in urban heating and HVAC, petrochemical and chemical industries, power industry, metallurgical industry, shipbuilding and marine engineering, and other fields. It solves many problems caused by displacement, vibration, and sealing in rigid systems, greatly improving the safety, stability, and reliability of the system.

This metal expansion joint forming machine/expansion joint rib expansion machine is mainly used for corrugated pipe compensators and expansion pipe rib forming, pressing uneven ribs onto the cylindrical wall. Larger sizes can be customized.

This machine has a high degree of automation. Operators can complete one process cycle with a single button press, making work easy, ensuring stable quality, and high production efficiency; it also has strong adjustability. Adjustable feed speed and stroke length make it suitable for processing products of different diameters and heights, offering multiple functions in one machine; user-friendly operating system for easy operation, installation, and debugging; energy-saving. Developed and equipped with new forming processes, achieving stable production with low energy consumption.

Process Advantages:

1. This corrugated pipe compensator forming machine produces expansion pipes with smooth, wrinkle-free, burr-free ribs, standard dimensions, and consistent, uniform corrugation height!

2. This machine is more efficient than traditional manual rib forming machines;

3. This rib forming machine is suitable for rib forming and expansion of thick stainless steel and multi-layer boards.

1. Non-standard customization: meet personalized technical requirements.

2. Samples and drawings: professional R&D team design.

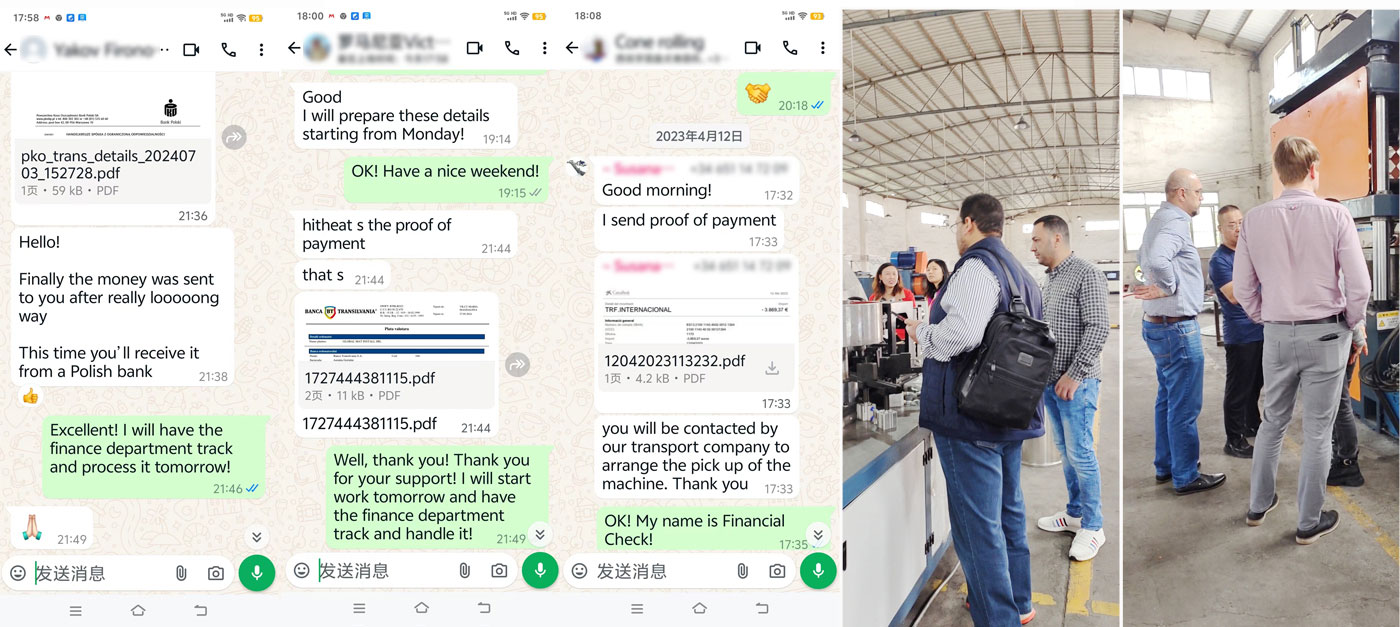

3. Flexible payment: T/T, LC, international bank.

4. Video factory inspection: can be scheduled.

5.Experienced professional sales service team.

6. Visual production process.

1. Provide circuit diagrams, maintenance manuals,full-course teaching videos and other materials required.

2. Full-time after-sales service, cooperate with customers to inspect, install and test.

3. Quick response: respond within 24 hours if there are any problems with the customers use.

| Stainless Steel Thickness: | Within 3mm |

Pipe Inner Diameter: | 350-1500mm |

Corrugation Height: | 0-70mm |

Blank Tube Height: | 1230mm |

| Power Supply Type: | 380V Three-phase Four-wire |

| Total Power: | 22.6KW |

| Equipment Weight: Approx. | 4000kg |

| Drive Method: | Hydraulic |

| Control Method: | PLC Touch Screen |

| Action Mode: | Manual/Automatic |

| Equipment Dimensions: | 1500x2000x2800 (Length, Width, Height) |

| Cylinder Tonnage: | 200t |

| Machine Function: | Corrugated Tube Forming. |

We are grateful for your support and trust along the way. We are honored by your cooperation every time, and we will live up to your trust and provide you with a more excellent experience.

We can also help you with all your equipment packaging needs. Whether you need split packaging, certified materials or general packaging advice, our team of experts can help you. We understand that every business is different, so we tailor our services to your needs. Our goal is to make your life easier by meeting all your packaging needs so that you can focus on running your business.

As a professional mechanical equipment manufacturer, our company is a private technology innovation enterprise integrating independent research and development, design and manufacturing, installation and commissioning, and training.

Our R&D team has 10 people, whose members cover multiple professional fields such as mechanical engineering, electronic information, and materials science, and have the ability to deal with different technical problems.

Our equipment is widely used in aerospace, energy, ventilation,hardware and furniture, tableware, medicine, electricity, packaging,construction,automobile and other industries and fields.

Q: When shipping, what kind of packing?

A: We use standard export packing.

Q: What are your delivery terms?

A: EXW, FOB, CFR, CIF.

Q: What's your delivery time?

A: Generally speaking, it takes 30 to 60 days after receiving your advance payment. The specific delivery time depends on the item and quantity of your order.

Q: Can you make it as required?

A: Yes, we can produce according to your samples or technical drawings. We can make molds and fixtures.

Q: Do you have professional engineers?

A: Yes.we have professional engineers and designers.

Q: Can you provide customzied machines?

A:Yes, we can design and manufacture according to your specific requirements.