The Automatic Curling Machine is an automated curling device primarily used for curling metal materials. It utilizes an automated control system to precisely control the curling process, improving production efficiency and product quality. This equipment is widely used in the metalworking industry and is suitable for curling a variety of metal materials. Compared to traditional manual curling methods, the Automatic Curling Machine significantly reduces manual intervention and labor intensity while ensuring consistent and stable curling results. It plays a vital role in the modern metalworking industry and is a key piece of equipment for improving production automation and product quality.

1. Sturdy Construction:

The Metal Cylinder Hydraulic Automatic Curling Machine features a sturdy construction, ensuring stability during processing. The frame provides solid support for the entire machine, preventing shaking during operation and guaranteeing precision and quality. This design ensures high performance even during extended operation, providing reliable support for metal processing.

2. Efficient Curling Mechanism:

The curling mechanism is the core component of the Automatic Curling Machine and includes the curling wheel and pressure roller. Through precise motion and pressure control, it achieves high-quality curling results. This mechanism utilizes advanced design and manufacturing processes to ensure efficient and accurate curling, meeting the requirements of diverse metal materials and processing.

3. Powerful Drive System:

The drive system provides power to the curling mechanism, ensuring normal operation. The system offers options for motor, hydraulic, or pneumatic drive to meet diverse processing requirements. The motor drive system utilizes a high-efficiency motor, providing stable and powerful power output, ensuring a continuous and stable curling process.

4. Intelligent Control System:

The control system is the brain of the Automatic Curling Machine, controlling operating parameters such as curling speed and pressure. It utilizes a PLC touchscreen control system for easy operation and a user-friendly interface. Operators can easily set and adjust parameters via the touchscreen, achieving precise control and improving production efficiency and product quality.

5. High-Precision Processing:

The machine utilizes high-precision mechanical components and advanced manufacturing processes to ensure high precision during the curling process. Core components such as the curling wheel and pressure roller undergo precision machining and rigorous testing to ensure dimensional accuracy and surface quality. Furthermore, the machine's control system precisely controls curling speed and pressure, further enhancing the accuracy and consistency of curling results.

6. Wide Application:

The Automatic Curling Machine is suitable for a wide range of industries and applications, including building material stores, machine repair shops, manufacturing plants, and ventilation equipment manufacturers. It can process metal cylinders with diameters ranging from 150 to 800 mm and thicknesses of 0.6 to 3 mm, meeting the needs of diverse customers. Its efficiency and reliability make it an ideal choice for the metalworking industry.

7. Reliable Core Components:

The equipment's core components, including the PLC, engine, bearings, gearbox, motor, gears, and pump, are all made of high-quality materials and advanced manufacturing processes. These components undergo rigorous quality testing to ensure performance and reliability. Furthermore, the equipment comes with a one-year warranty on core components, ensuring peace of mind.

8. Comprehensive After-Sales Service:

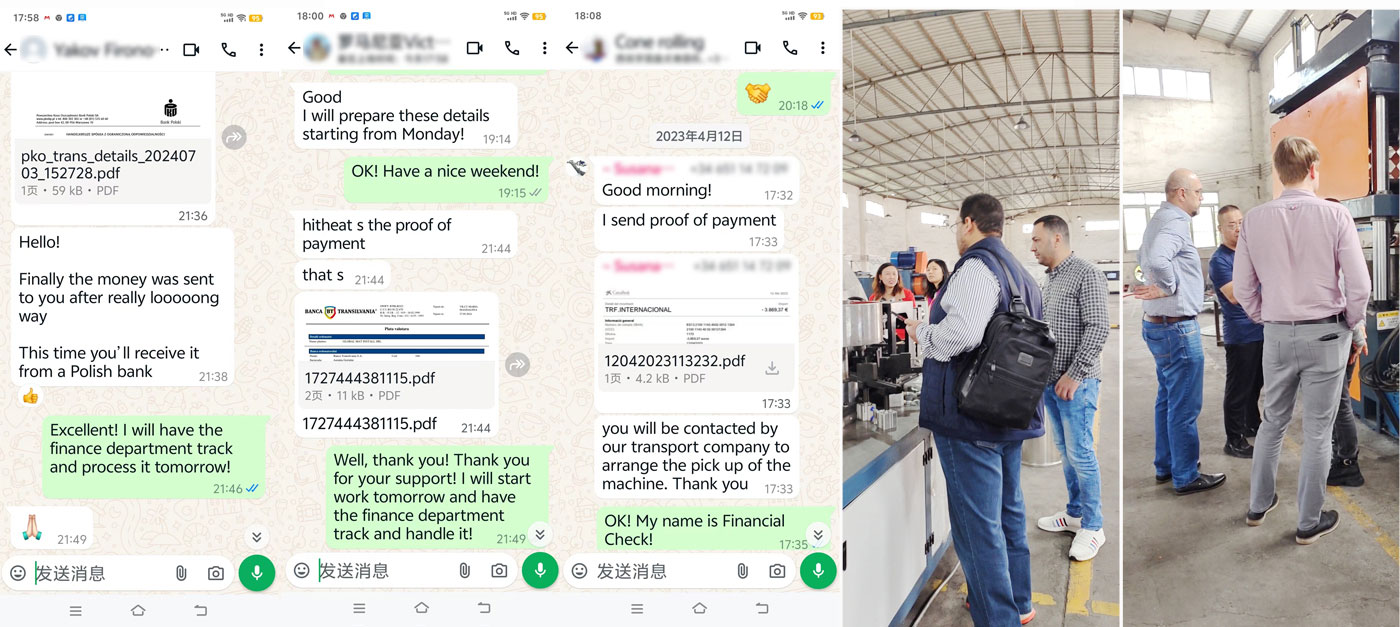

The Zhuosheng brand offers comprehensive after-sales service, including equipment installation and commissioning, operator training, technical consultation, and repair and maintenance. Customers can enjoy video factory inspections and mechanical test reports to ensure equipment quality and performance. Furthermore, the equipment comes with a one-year warranty, ensuring peace of mind during use.

| Origin: | Guangdong, China |

| Machine type: | cold forging machine |

| Weight (KG): | 1200 |

| Video factory inspection: | provided |

| Mechanical test report: | provided |

| Sales type: | general products |

| Core component warranty: | 1 year |

| Core components: | PLC, engine, bearing, gearbox, motor, gear, pump |

| Warranty: | 1 year |

| Main selling point: | easy operation |

| Applicable industries: | building materials stores, machinery repair shops, manufacturing plants, other, ventilation equipment manufacturers |

| Showroom location: | none |

| Brand: | Zhuosheng |

| Condition: | brand new |

| Power type: | AC 380V three-phase four-wire 50-60Hz |

| Equipment power: | 10.5kw |

| Equipment specifications: | 1800x1200x1800 (mm) |

| Workpiece diameter: | 150-800 (mm) |

| Thickness of workpiece: | 0.6-3 (mm) |

| Control method: | PLC touch screen |

| Scope of application: | cylindrical hardware sheet metal processing |

1. Non-standard customization: meet personalized technical requirements.

2. Samples and drawings: professional R&D team design.

3. Flexible payment: T/T, LC, international bank.

4. Video factory inspection: can be scheduled.

5.Experienced professional sales service team.

6. Visual production process.

1. Provide circuit diagrams, maintenance manuals,full-course teaching videos and other materials required.

2. Full-time after-sales service, cooperate with customers to inspect, install and test.

3. Quick response: respond within 24 hours if there are any problems with the customers use.

1. Building Materials Processing:

In the building materials industry, the Metal Cylinder Hydraulic Automatic Curling Machine can be used to process a variety of metal pipes and cylinders, such as ventilation ducts and storm drain pipes. It quickly and efficiently completes the curling process, improving production efficiency and ensuring product quality, meeting the high demands of the construction industry for metal material processing.

2. Machinery Repair and Manufacturing:

For machinery repair shops and manufacturers, this machine can be used to repair and manufacture various metal parts. It can repair damaged metal cylinders by curling them, restoring their original function and extending the service life of the parts. It can also be used to manufacture new metal parts, improving production efficiency and quality while reducing production costs.

3. Ventilation Equipment Manufacturing:

In the field of ventilation equipment manufacturing, the Automatic Curling Machine is an indispensable piece of equipment. It can process a variety of ventilation ducts and accessories, such as ducts, elbows, and tees. Through precise curling, it ensures the airtight seal and smooth airflow of ventilation equipment, improving the performance and efficiency of ventilation systems.

4. Hardware Processing:

This equipment is suitable for processing hardware products such as metal barrels, cans, and boxes. It can curl metal sheets to create various shapes. Through automated control and high-precision processing, it ensures consistent product quality and aesthetic appearance, enhancing product competitiveness.

5. Automotive Parts Manufacturing:

In automotive parts manufacturing, the Automatic Curling Machine can be used to process metal parts such as automotive wheels and exhaust pipes. It achieves high-precision curling, ensuring component quality and performance, meeting the stringent requirements of the automotive industry. Through automated production, it improves production efficiency and quality stability, while reducing production costs.

6. Other Industry Applications:

In addition to the industries listed above, the Automatic Curling Machine can also be used in other fields requiring metal curling, such as home appliance manufacturing, shipbuilding, and aerospace. It can be customized to meet specific processing requirements, providing efficient and reliable solutions for metal processing in various industries.

The working principle of the metal cylinder curling machine is to use the curling mechanism to curl the edge of the metal cylinder. First, place the metal cylinder to be processed in a suitable position, and then start the equipment. The drive system drives the curling mechanism to move, and the curling wheel and pressure wheel and other components apply pressure and rotational force to the edge of the cylinder, so that the metal edge gradually curls into the desired shape. During the whole process, the control system can adjust the curling speed, pressure and other parameters as needed to ensure the stability and consistency of the curling quality.

We are grateful for your support and trust along the way. We are honored by your cooperation every time, and we will live up to your trust and provide you with a more excellent experience.

We can also help you with all your equipment packaging needs. Whether you need split packaging, certified materials or general packaging advice, our team of experts can help you. We understand that every business is different, so we tailor our services to your needs. Our goal is to make your life easier by meeting all your packaging needs so that you can focus on running your business.

As a professional mechanical equipment manufacturer, our company is a private technology innovation enterprise integrating independent research and development, design and manufacturing, installation and commissioning, and training.

Our R&D team has 10 people, whose members cover multiple professional fields such as mechanical engineering, electronic information, and materials science, and have the ability to deal with different technical problems.

Our equipment is widely used in aerospace, energy, ventilation,hardware and furniture, tableware, medicine, electricity, packaging,construction,automobile and other industries and fields.