Jiangmen Zhuosheng Machinery - ZS-FB-400-2 Automatic Flanging Machine for Motor Casings | Made in China by a Powerful Factory.

Jiangmen Zhuosheng Machinery Co., Ltd., a leading manufacturer in China's machinery manufacturing sector, specializes in the development of custom-made equipment. We offer the ZS-FB-400-2 high-precision automatic flanging machine, specifically designed for flanging small-diameter motor casings. Dual servo motors ensure long-term accuracy, and comprehensive after-sales support is available.

Power Empowers Precision Manufacturing: Zhuosheng Machinery Launches the ZS-FB-400-2 automatic flanging machine for Motor Casings

Jiangmen Zhuosheng Machinery Co., Ltd., a leading manufacturer specializing in custom-made automation equipment in China's machinery manufacturing sector, has officially launched its masterpiece, the ZS-FB-400-2 Automatic Hydraulic Flanging Machine. This machine, the product of fifteen years of industry insight and technological accumulation, is designed to provide the ultimate solution for flanging small-diameter motor casings in the micro-motor and servo motor industries, redefining the benchmark for efficiency and precision.

1. [Profound R&D and Design: The Result of Fifteen Years of Team Experience]

This machine was developed by our experienced design team with fifteen years of industry experience. They deeply understand the core challenges of the flanging process and, as a result, incorporate a unique upper and lower synchronized hydraulic system, ensuring the machine's fundamental stability and advancement from the ground up. This is more than just an automatic flanging machine; it embodies our technological wisdom.

2. [Continuously Refined Quality Control System: Multiple Inspections Before Shipment]

Jiangmen Zhuosheng Machinery Co., Ltd. is proud to rigorously implement its "Supervisor - Factory Manager - Designer - Commissioning - Manager" multi-inspection process. Every ZS-FB-400-2 flanging machine undergoes rigorous testing that far exceeds industry standards before shipment. We guarantee its robust materials and sturdy construction, ensuring virtually no instability issues.

3. [High-End Configuration: Key Components from Well-Known Brands]

To ensure the long-term reliability of this equipment, we insist on using high-quality components. The core control system utilizes a Delta PLC and a Weilun touchscreen; power and precision are ensured by Qike servo motors and a Taichuang hydraulic system; key transmission components utilize NSK/Harbin bearings and Lepid guides. This ensures long-term, stable operation of this motor housing flanging machine in the customer's factory.

4. [Customer-Focused Customization: Your Needs Are Our Standards]

"Customization" is the core DNA of Jiangmen Zhuosheng Machinery Co., Ltd. We understand that standard equipment cannot meet all requirements. Therefore, the tooling, travel, and even functional modules of this flanging machine can be customized according to your workpiece drawings. We provide not just a cold machine, but a complete flanging solution.

This machine is designed specifically for small-diameter motor housings with a diameter of 100-400mm, demonstrating its robust processing capabilities with flanging thicknesses (2-4mm for iron plates and 1-2.5mm for stainless steel). Dual servo motors ensure ultra-high precision of ±0.5mm, unaffected by gear wear.

We have a strong after-sales team, offering on-site installation, commissioning, and operator training. We solemnly promise 24-hour response time during the warranty period and lifetime after-sales service. Choosing Zhuosheng means choosing long-term protection.

This ZS-FB-400-2 automatic flanging machine embodies the manufacturing strength, quality philosophy, and service commitment of Jiangmen Zhuosheng Machinery Co., Ltd. It is not only an efficient tool for your production line, but also a trusted long-term partner. We look forward to using our strength to create real value for you.

1. Non-standard customization: meet personalized technical requirements.

2. Samples and drawings: professional R&D team design.

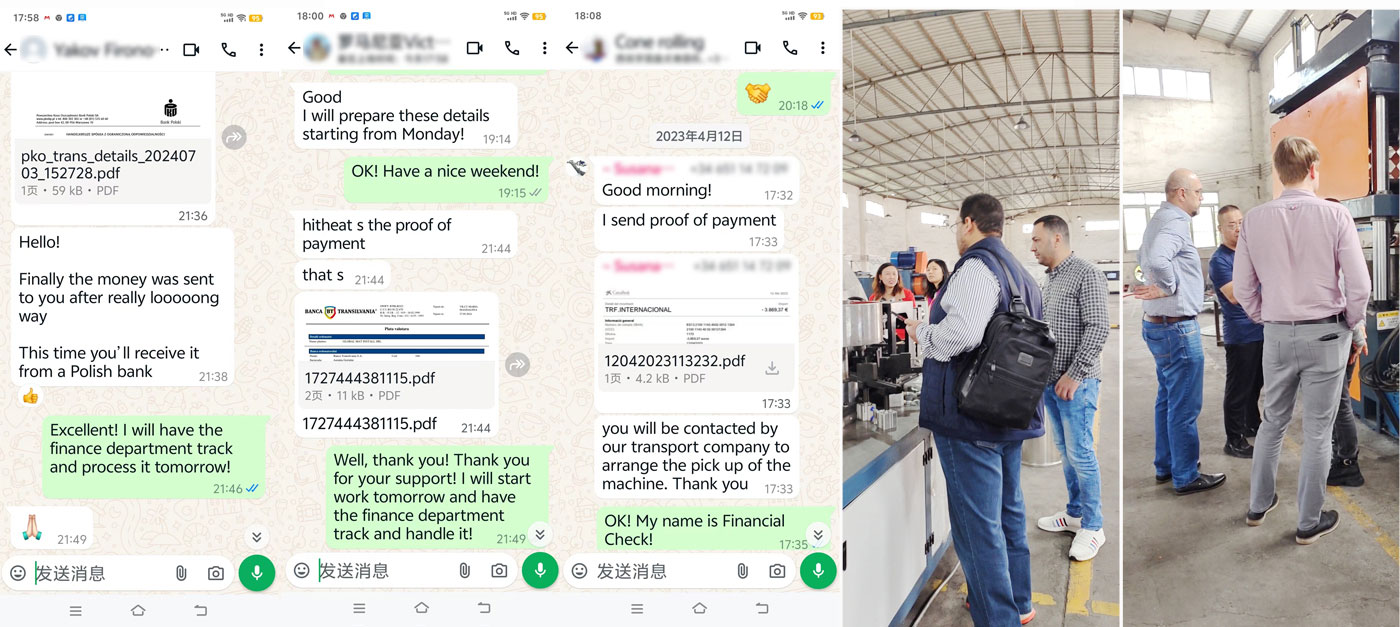

3. Flexible payment: T/T, LC, international bank.

4. Video factory inspection: can be scheduled.

5.Experienced professional sales service team.

6. Visual production process.

1. Provide circuit diagrams, maintenance manuals,full-course teaching videos and other materials required.

2. Full-time after-sales service, cooperate with customers to inspect, install and test.

3. Quick response: respond within 24 hours if there are any problems with the customers use.

| Power Supply: | AC 380V, three-phase, four-wire, 50Hz (customizable for international applications) |

| Power: | 7.5kW |

| Model: | ZS-FB-400-2 |

| Working Diameter Range: | 100-400mm |

| Workpiece Height: | 200-1000mm |

| Flange Width: | 10-40mm |

| Working Materials: | Iron, Stainless Steel |

| Flange Thickness: | 1-4mm for Iron; 1-2.5mm for Stainless Steel |

| Function: | Flanging of upper and lower ends of cylinders |

| Power: | Hydraulic/Pneumatic |

| Control: | PLC + Touchscreen |

| Weight: | Approximately 2.5 tons |

| Dimensions: | 2000*1900*2500mm |

We are grateful for your support and trust along the way. We are honored by your cooperation every time, and we will live up to your trust and provide you with a more excellent experience.

We can also help you with all your equipment packaging needs. Whether you need split packaging, certified materials or general packaging advice, our team of experts can help you. We understand that every business is different, so we tailor our services to your needs. Our goal is to make your life easier by meeting all your packaging needs so that you can focus on running your business.

As a professional mechanical equipment manufacturer, our company is a private technology innovation enterprise integrating independent research and development, design and manufacturing, installation and commissioning, and training.

Our R&D team has 10 people, whose members cover multiple professional fields such as mechanical engineering, electronic information, and materials science, and have the ability to deal with different technical problems.

Our equipment is widely used in aerospace, energy, ventilation,hardware and furniture, tableware, medicine, electricity, packaging,construction,automobile and other industries and fields.