The Automatic Hydraulic Flanging Machine is an advanced piece of equipment used in the sheet metal industry to perform flanging operations on various metal sheets. This machine utilizes hydraulic power to ensure consistent and precise flanging results.

The hydraulic power system provides an even force distribution across the entire length of the material, ensuring uniform flanging without distortion. The machine operates with a hydraulic pressure of up to 200 tons, capable of handling heavy-duty applications.

This machine offers flanging angles adjustable from 45° to 180°, allowing for customization to meet different project needs. The flange height can be adjusted up to 10mm for seamless integration with other components.

With an intuitive digital interface, operators can easily set parameters for different jobs. This machine supports up to 100 pre-stored programs, significantly reducing setup time between different products.

The safety system includes light curtains for detecting human presence in hazardous areas and an emergency stop feature for immediate shutdown in case of emergencies.

An automatic sheet feeding mechanism is included, which increases production speed and reduces operator intervention, boosting productivity.

The machine's heavy-duty steel construction ensures long-term durability. Regular maintenance checks and lubrication points are strategically placed for easy access.

It includes an energy-saving mode that reduces power consumption during idle times, making it eco-friendly.

Here are the key specifications for the Automatic Hydraulic Flanging Machine:

| Specification | Details |

|---|---|

| Model | HFM-200T |

| Hydraulic Pressure | 200T (tons) |

| Maximum Sheet Width | 3000mm |

| Maximum Sheet Thickness | 8mm |

| Flanging Angle Range | 45° to 180° |

| Flange Height | Up to 10mm |

| Operating Speed | Adjustable, up to 15 flanges per minute |

| Size of Machine | 5200mm x 3500mm x 2000mm |

| Weight | 8000kg |

| Power Supply | 380V/50Hz, 3 Phase |

| Control System | PLC with Touch Screen Interface |

Trunk lids, hoods, and body panels: Providing flanging for assembly and aesthetic purposes.

Furniture parts: Flanging for edge bending to create smooth corners on steel frames or shelves.

Housings for electronic devices: Producing flanges for securing covers and panels.

Structural components: Flanging steel for use in beams, columns, or brackets.

Refrigerator doors, washing machine drums: Ensuring a professional finish with flanged edges.

Wipe down: Clean the machine daily to remove metal dust, coolant, and debris, preventing damage to moving parts.

Lubricate: Regularly lubricate all bearings, gears, and hydraulic systems as per the maintenance schedule.

Routine checks: Inspect seals, hydraulics, and electronic components for signs of wear or leakage.

Scheduled service: Follow manufacturer's recommended intervals for maintenance to prevent major breakdowns.

Q1: Can I flange materials other than steel?

Yes, the machine can flange aluminum, stainless steel, and other sheet metals with the right tooling.

Q2: How long does it take to change the tooling?

Tool changes can be completed in around 30 minutes with the preset programs.

Q3: What's the training process for operators?

Training includes safety procedures, operation, and maintenance to ensure proper machine handling.

Q4: How do I know when to replace the hydraulic oil?

Typically, hydraulic oil should be replaced every 3000 hours or as recommended by the manufacturer.

Q5: Are there custom options available for this machine?

Yes, customizations like extended width, thickness capacity, and specialized tooling are available.

Q6: Can this machine handle curved sheets?

It's designed primarily for flat sheets, but modifications can be made to process curved ones.

Q7: What support does the manufacturer provide?

Comprehensive support includes on-site service, remote assistance, and access to a detailed knowledge base.

| Power supply type: | AC 380V (customizable according to different countries) three-phase four-wire |

| Total equipment power: | about 15kw |

| Equipment specifications: | about 3300x2100x1900 (MM) |

| Processing product diameter: | 400-1600MM |

| Processing product thickness: | 2-6MM (carbon steel) ,2-4MM (stainless steel) |

| Processing product height: | blank size within 100-1600MM |

| Flanging width: | 20-60MM |

| Configuration mold specifications: | 400--1600mm |

| Punching accuracy range: | ± 1.0MM |

| Punching diameter: | 5-16MM |

| Equipment weight: | 4.9 tons |

1. Non-standard customization: meet personalized technical requirements.

2. Samples and drawings: professional R&D team design.

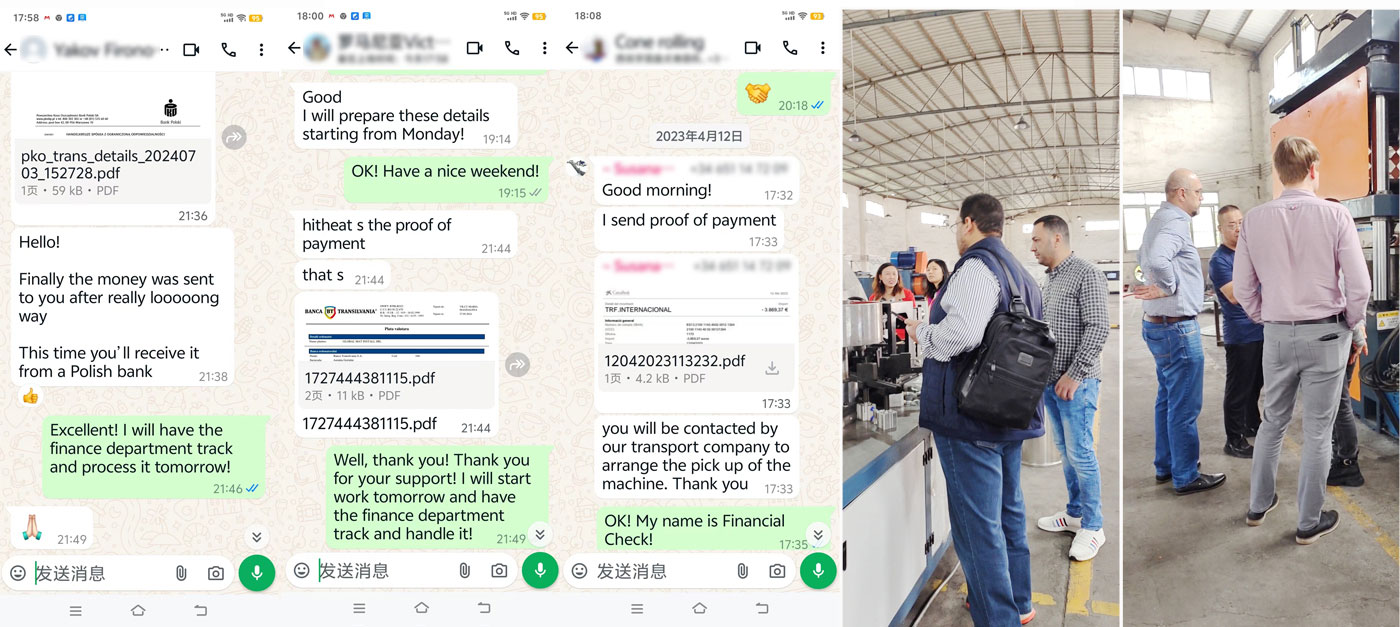

3. Flexible payment: T/T, LC, international bank.

4. Video factory inspection: can be scheduled.

5.Experienced professional sales service team.

6. Visual production process.

1. Provide circuit diagrams, maintenance manuals,full-course teaching videos and other materials required.

2. Full-time after-sales service, cooperate with customers to inspect, install and test.

3. Quick response: respond within 24 hours if there are any problems with the customers use.

We are grateful for your support and trust along the way. We are honored by your cooperation every time, and we will live up to your trust and provide you with a more excellent experience.

We can also help you with all your equipment packaging needs. Whether you need split packaging, certified materials or general packaging advice, our team of experts can help you. We understand that every business is different, so we tailor our services to your needs. Our goal is to make your life easier by meeting all your packaging needs so that you can focus on running your business.

As a professional mechanical equipment manufacturer, our company is a private technology innovation enterprise integrating independent research and development, design and manufacturing, installation and commissioning, and training.

Our R&D team has 10 people, whose members cover multiple professional fields such as mechanical engineering, electronic information, and materials science, and have the ability to deal with different technical problems.

Our equipment is widely used in aerospace, energy, ventilation,hardware and furniture, tableware, medicine, electricity, packaging,construction,automobile and other industries and fields.