The Automatic Punching And Flanging Machine is a cutting-edge piece of machinery designed for the metalworking industry. It combines both punching and flanging operations into one unit, which significantly streamlines production processes and saves time and labor.

The Automatic Punching And Flanging Machine boasts high precision punching capabilities. With a positioning accuracy of ±0.1mm, this machine ensures that punches are made exactly where they are needed, providing consistent results across each cycle.

This machine offers flanging with an edge bend radius of up to 5mm, allowing for a variety of flange sizes tailored to different application needs. The flanging process can handle materials from 0.5mm to 3mm thick steel, aluminum, and other common metals.

Fully automated operations ensure minimal human intervention. The machine can be programmed to handle a sequence of punches and flanges, reducing operator errors and improving workflow efficiency.

With a rigid steel frame that supports the machine's weight and the forces exerted during punching and flanging, this machine offers durability and reliability over extensive production runs.

The machine features an intuitive touch-screen interface, making setup and operation straightforward. This interface allows for the adjustment of up to 100 different programs, enabling quick changes in production specifications.

It operates at a working speed of up to 12 punches per minute for punching and flanging speed of 5 strokes per minute, allowing for high output rates that are essential in industrial settings.

Here are the key specifications for the Automatic Punching And Flanging Machine:

| Specification | Details |

|---|---|

| Model | ZQ-4015S |

| Punching Force | 40T |

| Flanging Force | 25T |

| Punching Stroke | 40mm |

| Flanging Stroke | 50mm |

| Turret Positioning Accuracy | ±0.1mm |

| Flanging Radius Range | Up to 5mm |

| Workpiece Thickness | 0.5-3mm |

| Max. Workpiece Size | 2000mm x 1500mm |

| Machine Size | 3800mm x 2500mm x 2200mm |

| Weight | 6500kg |

| Power Supply | 380V/50Hz, 3 Phase |

| Control System | CNC Controller with Touch Screen Interface |

Car door frames and body parts: Flanging edges for aesthetic finishes and structural integrity.

Ducting: Punches for fastening joints and flanging for smoother airflow.

Panel enclosures: Producing precisely cut holes for switches, displays, and connectors.

Washing machines, dryers, and refrigerators: Flanging for securing internal components.

Building facades: Punching for window frames, and flanging for thermal breaks.

Regular cleaning: Remove dust, coolant residues, and metal chips to prevent tool wear.

Machine Exterior: Wipe down with a cloth soaked in a mild detergent solution to keep the machine looking new.

Apply lubricants: All moving parts, especially gears and lead screws, should be lubricated as per the manufacturer's recommendations.

Weekly Inspections: Check for any signs of wear, damage, or loss of accuracy in the punching and flanging tools.

Regular Calibration: Ensure punching accuracy by regularly checking and recalibrating as needed.

Scheduled Service: Follow a strict maintenance schedule to prevent unexpected machine downtime.

Q1: Can this machine handle non-ferrous materials?

Yes, it can process aluminum, copper, and other non-ferrous metals with specific tooling adjustments.

Q2: What's the typical setup time for a new job?

With the preset programs, setup time can be reduced to less than 10 minutes for most jobs.

Q3: Does the machine come with safety features?

Yes, it has light curtains and an emergency stop system to ensure operator safety.

Q4: Is there any training required for operators?

Basic training on operation, safety, and maintenance is provided with machine purchase.

Q5: How often should I expect to replace tooling?

Tool life depends on the material and frequency of use, but typically, every 3 to 6 months, or as per the wear and tear observed.

Q6: Can I customize the machine for specific needs?

Yes, custom tooling and programming options are available to meet specific production requirements.

Q7: What kind of after-sales support can I expect?

Comprehensive support including on-site service, remote troubleshooting, and access to an online knowledge base.

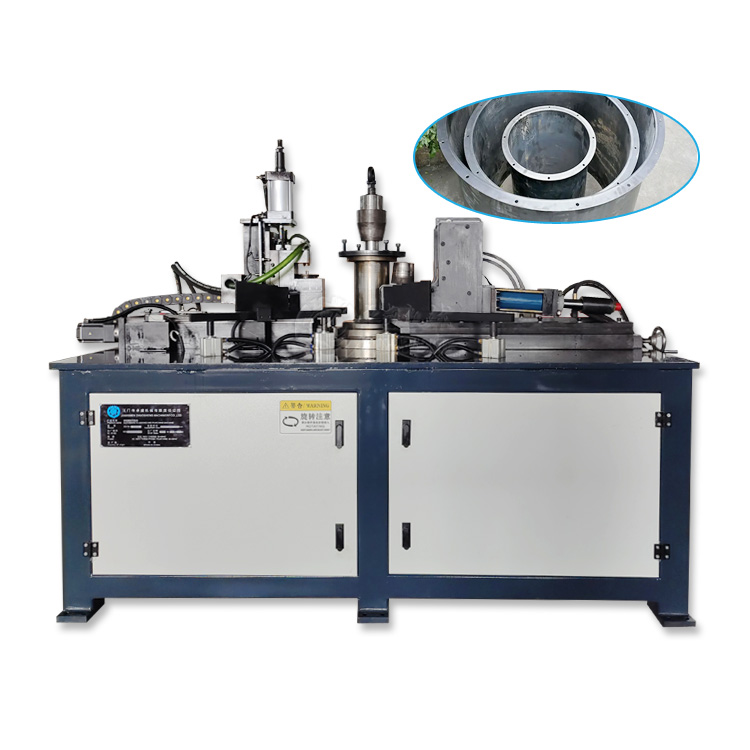

Heavy-duty structural design:

It has a sturdy body and workbench, which can withstand greater working pressure and weight, ensuring the stability and reliability of the equipment when processing heavy cylinders. This is especially important for processing large, thick-walled metal cylinders, which can ensure that there will be no deformation, vibration and other problems during the processing.

Two-station design:

It has two stations, one for flanging and the other for flange punching of the workpiece, thereby improving the working efficiency of the equipment and reducing the production cycle.

| Place of Origin: | Guangdong, China |

| Machine Type: | Cold Forging Machine |

| Weight (KG): | 2500 |

| Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided |

| Marketing Type: | Ordinary Product |

| Warranty of core components: | 1 Year |

| Core Components: | PLC, Motor |

| Warranty: | 1 Year |

| Key Selling Points: | Easy to Operate |

| Applicable Industries: | Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Construction works , Energy & Mining, Other |

| Showroom Location: | None |

| Power supply voltage:: | AC 380V three-phase four-wire 50-60 Hz |

| Total equipment power:: | 10.5KW |

| Processing product diameter:: | 300-800MM |

| Processing product thickness:: | carbon steel 2-6mm. |

| Flanging height:: | 200-450MM |

| Flanging width:: | 25-50mm |

| Punching diameter:: | 6-13mm |

| Control mode:: | PLC touch screen |

| Drive mode:: | hydraulic/electric |

1. Non-standard customization: meet personalized technical requirements.

2. Samples and drawings: professional R&D team design.

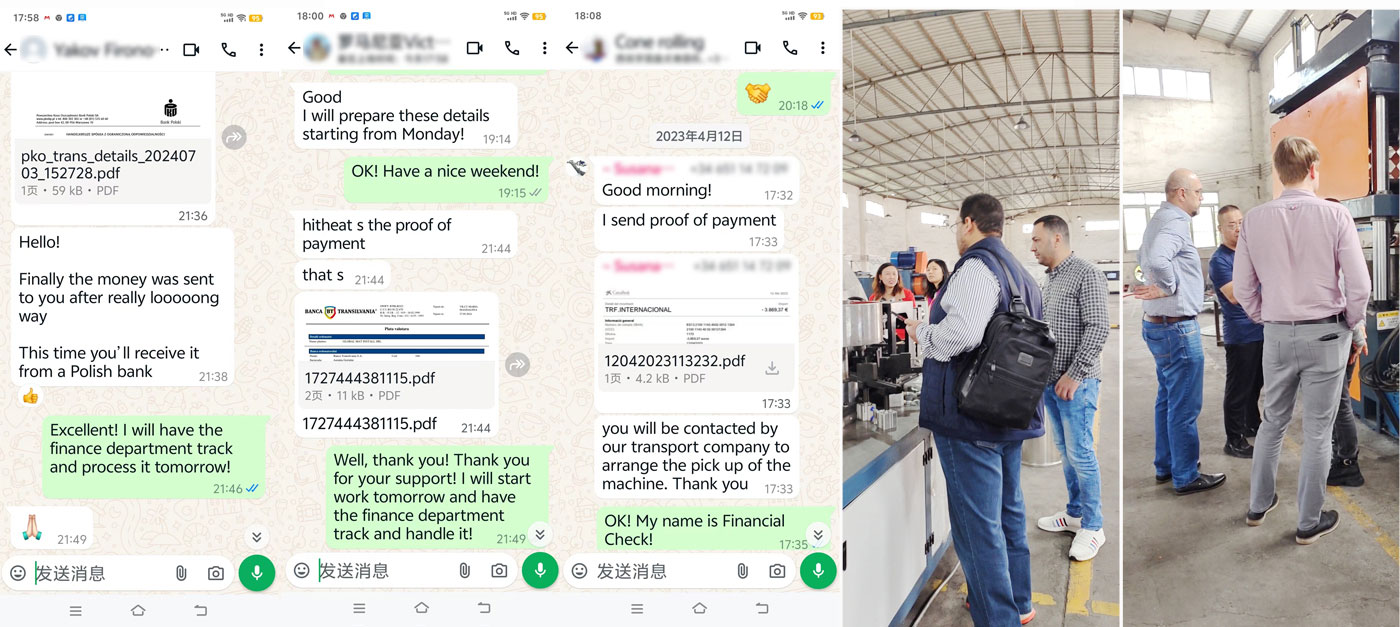

3. Flexible payment: T/T, LC, international bank.

4. Video factory inspection: can be scheduled.

5.Experienced professional sales service team.

6. Visual production process.

1. Provide circuit diagrams, maintenance manuals,full-course teaching videos and other materials required.

2. Full-time after-sales service, cooperate with customers to inspect, install and test.

3. Quick response: respond within 24 hours if there are any problems with the customers use.

- Pressure vessel manufacturing: In the production process of pressure vessels, the cylindrical tank body needs to be flanging and punching to meet the process requirements of welding, installation of accessories, etc. The heavy-duty 800-2-station cylinder flanging and punching all-in-one machine can efficiently and accurately complete these processing tasks to ensure the quality and safety of pressure vessels.

- Auto parts manufacturing: Many of the auto parts such as exhaust pipes, fuel tanks, filters, etc. are cylindrical, and the production of these parts requires flanging and punching. This equipment can meet the high-precision and high-efficiency requirements of auto parts manufacturing.

- Ventilation duct manufacturing: The connection parts of the ventilation duct usually need to be flanging to install flanges and other connectors. At the same time, ventilation holes need to be punched on the ventilation duct. The heavy-duty 800-2-station cylindrical flanging and punching machine can complete these processing operations at one time, improving the production efficiency and quality of the ventilation duct.

- The equipment usually adopts a hydraulic or pneumatic drive system to provide powerful power to drive the movement of the flanging and punching tools. When working, first fix the cylindrical workpiece on the workbench, and then set the parameters of flanging and punching through the control system, such as the angle of the flanging, the position and size of the punching, etc.

- After starting the equipment, the flanging tool and the punching tool will move according to the preset program to complete the flanging and punching of the cylinder. The whole process has a high degree of automation, which can greatly improve production efficiency and processing accuracy.

We are grateful for your support and trust along the way. We are honored by your cooperation every time, and we will live up to your trust and provide you with a more excellent experience.

We can also help you with all your equipment packaging needs. Whether you need split packaging, certified materials or general packaging advice, our team of experts can help you. We understand that every business is different, so we tailor our services to your needs. Our goal is to make your life easier by meeting all your packaging needs so that you can focus on running your business.

As a professional mechanical equipment manufacturer, our company is a private technology innovation enterprise integrating independent research and development, design and manufacturing, installation and commissioning, and training.

Our R&D team has 10 people, whose members cover multiple professional fields such as mechanical engineering, electronic information, and materials science, and have the ability to deal with different technical problems.

Our equipment is widely used in aerospace, energy, ventilation,hardware and furniture, tableware, medicine, electricity, packaging,construction,automobile and other industries and fields.

Q: When shipping, what kind of packing?

A: We use standard export packing.

Q: What are your delivery terms?

A: EXW, FOB, CFR, CIF.

Q: What's your delivery time?

A: Generally speaking, it takes 30 to 60 days after receiving your advance payment. The specific delivery time depends on the item and quantity of your order.

Q: Can you make it as required?

A: Yes, we can produce according to your samples or technical drawings. We can make molds and fixtures.

Q: Do you have professional engineers?

A: Yes.we have professional engineers and designers.

Q: Can you provide customzied machines?

A:Yes, we can design and manufacture according to your specific requirements.