Hydraulic Flanging Machine is a special equipment powered by a hydraulic transmission system, mainly used for flanging of metal sheets. The high-pressure oil generated by the hydraulic system pushes the piston or cylinder to apply the pressure required for flanging to the workpiece, thereby achieving flanging of the edge of the metal sheet and improving the strength and beauty of the workpiece.

1. Powerful hydraulic system

The Hydraulic Flanging Machine is equipped with an advanced hydraulic system that can generate up to tens of tons or even hundreds of tons of pressure to meet the flanging needs of metal sheets of different materials and thicknesses. The hydraulic system is controlled by a high-precision proportional valve to achieve precise adjustment of pressure, speed and position to ensure the stability and consistency of the flanging process.

2. Flexible mold replacement

The equipment is designed with a structure for quick mold replacement. Users can easily replace flanging molds of different specifications according to processing requirements to achieve multiple uses of one machine. The mold is made of high-quality alloy steel material, and after precision processing and heat treatment, it has the characteristics of high hardness, high wear resistance and long life.

2. High-efficiency processing efficiency

The hydraulic flanging machine adopts high-speed hydraulic blowing head or hydraulic cylinder drive to achieve fast flanging processing and greatly improve production efficiency. The equipment is equipped with an automated control system to achieve a continuous and stable processing process, reduce manual intervention, and reduce labor intensity.

3. Reliable safety performance

The equipment is designed with complete safety protection devices, such as safety light curtains, emergency stop buttons, etc., to ensure the safety of operators. The hydraulic system adopts safety measures such as overload protection and pressure release to prevent the equipment from being damaged due to overload or abnormal conditions.

4. Accurate positioning system

The hydraulic flanging machine is equipped with a high-precision positioning system to ensure the accurate position of the workpiece during the flanging process and improve the processing accuracy and consistency. The positioning system is driven by a servo motor or a stepper motor to achieve fast and accurate positioning adjustment to meet the processing needs of different workpieces.

1. Automobile manufacturing industry

In the process of automobile manufacturing, hydraulic flanging machines are widely used in flanging processing of parts such as doors, hoods, and trunk lids to improve the strength and sealing of parts.

2. Aerospace field

The aerospace field has extremely high requirements for the processing accuracy and strength of metal sheets. Hydraulic flanging machines can meet this demand and are used for flanging of aircraft fuselages, wings and other parts.

3. Home appliance production industry

In home appliance production, hydraulic flanging machines are used for flanging of the outer shells of products such as refrigerators and washing machines to improve the beauty and durability of the products.

4. Building decoration industry

In the building decoration industry, hydraulic flanging machines can be used for flanging of metal doors, windows, curtain walls and other parts to increase the strength and decorative effect of the parts.

5. Other metal processing fields

Hydraulic flanging machines can also be used for flanging of metal parts such as pipe connectors and flanges to meet the processing needs of different industries.

1. Daily cleaning

After each use, the oil and debris on the surface of the equipment should be cleaned in time to keep the equipment clean.

Regularly check the oil level and oil quality of the hydraulic system to ensure that the hydraulic oil is clean and free of impurities.

2. Hydraulic system maintenance

Replace the hydraulic oil filter regularly to prevent impurities from entering the hydraulic system and affecting the performance of the equipment.

Check the seals and pipe connections of the hydraulic system regularly to prevent oil leakage.

3. Mold maintenance

The mold should be cleaned in time after use to remove oil and metal chips on the surface to prevent rust or damage to the mold.

Lubricate and maintain the mold regularly to extend the service life of the mold.

4. Electrical system inspection

Check the wiring and components of the electrical system regularly to ensure that the electrical system is safe and reliable.

Prevent the electrical system from getting damp or getting water in to avoid short circuits or electric shock accidents.

1. What materials are suitable for the processing of metal sheets of hydraulic flanging machines?

Hydraulic flanging machines are suitable for the processing of metal sheets of various materials such as stainless steel, carbon steel, aluminum alloy, etc. The specific scope of application needs to be determined according to the equipment model and mold specifications.

2. How to choose a suitable flanging mold?

When selecting a flanging mold, it is necessary to comprehensively consider factors such as the material, thickness and flanging size of the workpiece to be processed. It is recommended to consult the equipment supplier or mold manufacturer for professional selection suggestions.

3. How to ensure the processing accuracy of the hydraulic flanging machine?

The processing accuracy of the hydraulic flanging machine is affected by many factors such as equipment performance, mold accuracy, and operating level. To ensure processing accuracy, the equipment needs to be calibrated and maintained regularly, high-precision molds need to be used, and the training and management of operators need to be strengthened.

4. What should I do if the hydraulic flanging machine leaks oil?

When oil leakage occurs, the machine should be stopped immediately for inspection to find out the cause of the oil leakage and repair it. Common causes of oil leakage include aging of seals, loose pipe connections, etc., and seals need to be replaced or pipe connections need to be tightened in time.

5. How often does the hydraulic oil of the hydraulic flanging machine need to be replaced?

The replacement cycle of hydraulic oil depends on factors such as the frequency of use of the equipment, the working environment, and the oil quality. It is generally recommended to replace the hydraulic oil every six months to one year, or replace it according to the recommendations of the equipment manufacturer.

6. Can the hydraulic flanging machine achieve automated production?

Some high-end hydraulic flanging machines are equipped with an automated control system, which can realize linkage control with loading and unloading devices, testing equipment, etc., to achieve automated production. However, the specific degree of automation needs to be determined according to the equipment model and configuration.

Structural Features:

1. Sturdy body: It is welded with high-strength steel, with sufficient rigidity and stability to withstand strong pressure and vibration during processing.

2. High-precision molds: Equipped with high-precision rib pressing, punching and flanging molds to ensure processing accuracy and quality. The material of the mold is usually high-quality alloy steel, which has good wear resistance and durability after precision processing and heat treatment.

3. Automatic control system: Advanced automatic control systems such as PLC controllers or CNC systems are used to realize the automatic operation of the equipment. The operator can input the processing parameters through the touch screen or control panel, and the equipment will automatically complete the processing process to improve production efficiency and processing accuracy.

4. Safety protection devices: In order to ensure the safety of the operator, the equipment is equipped with complete safety protection devices, such as protective covers, safety doors, emergency stop buttons, etc. During the operation of the equipment, these devices can effectively prevent accidents.

Advantages:

1. Efficient production: The automated processing process can greatly improve production efficiency and reduce the time and labor intensity of manual operation.

2. High-precision processing: High-precision molds and automated control systems ensure the stability of processing accuracy and quality.

3. Versatility: One device can complete multiple processing operations such as rib, punching and flange flanging, with strong versatility and adaptability.

4. Easy operation: The automated control system makes the operation of the equipment easier, and operators only need simple training to master the operation of the equipment.

5. Safe and reliable: The perfect safety protection device and stable body structure ensure the safe and reliable operation of the equipment and reduce the risk of accidents.

| Power type: | 380v three-phase 5-wire |

| Equipment weight: | 5.8t |

| Equipment total power: | 15kw |

| Equipment function: | flanging, punching, rib pressing. |

| Equipment processing size: | 400-1600MM (or 250-1300) |

| Equipment processing thickness: | 0.6-6mm |

| Equipment rib pressing size: | flanging flange edge within 200mm from rib center |

| Control mode: | PLC touch screen |

| Punching quantity: | 0-100 arbitrary |

| Equipment specifications: | 2900x2300x1700mm |

1. Non-standard customization: meet personalized technical requirements.

2. Samples and drawings: professional R&D team design.

3. Flexible payment: T/T, LC, international bank.

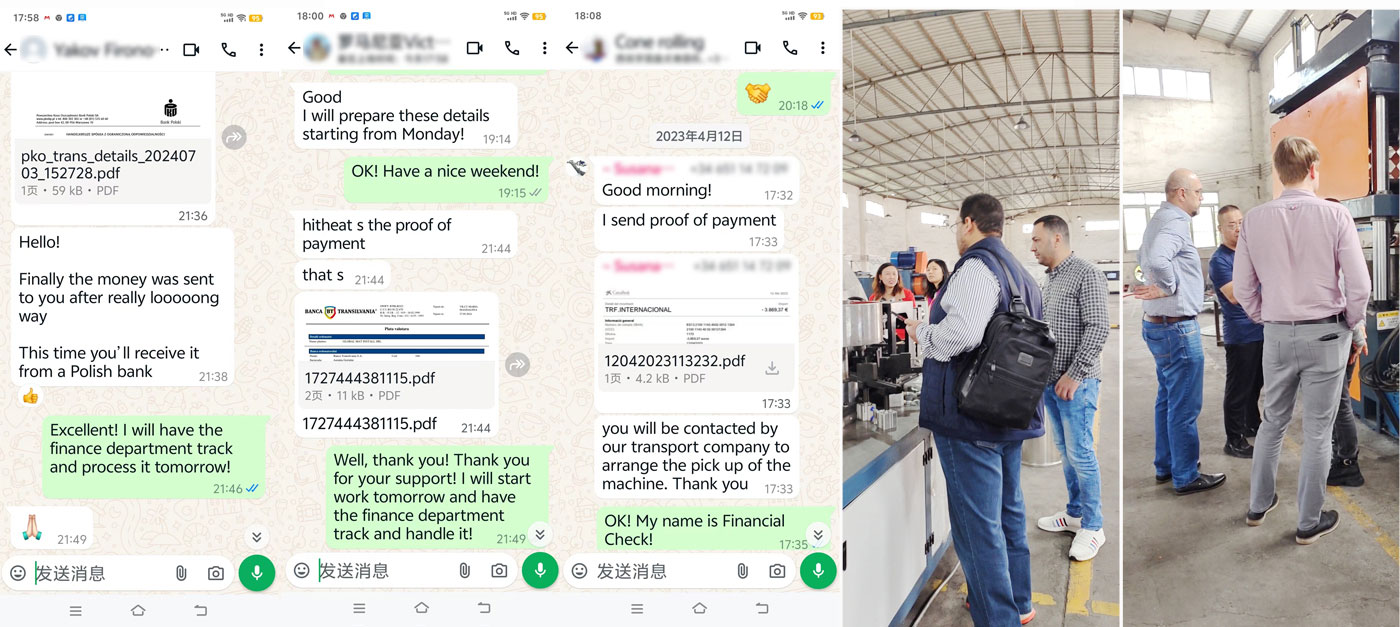

4. Video factory inspection: can be scheduled.

5.Experienced professional sales service team.

6. Visual production process.

1. Provide circuit diagrams, maintenance manuals,full-course teaching videos and other materials required.

2. Full-time after-sales service, cooperate with customers to inspect, install and test.

3. Quick response: respond within 24 hours if there are any problems with the customers use.

1. Pressure vessel manufacturing: In the production process of pressure vessels, the cylinder needs to be processed by rib pressing, punching and flange flanging to meet the structural strength and connection requirements of the container. The automatic hydraulic cylinder rib punching flange flanging machine can efficiently complete these processing tasks and improve the production efficiency and quality of pressure vessels.

2. Pipeline engineering: In the pipeline system, cylindrical pipe connectors usually need to be processed by rib, punching and flange flanging to connect with other pipeline components. This equipment can provide high-quality processing solutions for pipeline engineering.

3. Mechanical manufacturing: In the field of mechanical manufacturing, some cylindrical parts also need to be processed by rib, punching and flange flanging to meet specific structural and connection requirements. The automatic hydraulic cylinder rib punching flange flanging machine can provide efficient and precise processing services for mechanical manufacturing enterprises.

1. Hydraulic drive system: The high-pressure oil generated by the hydraulic pump drives the actuators such as hydraulic cylinders or hydraulic motors. These actuators provide powerful power to drive tools such as embossing, punching and flanging to perform precise processing actions.

2. Embossing process: Through a specific embossing die, regular raised patterns are formed on the surface of the cylinder to increase the strength and rigidity of the cylinder. The depth and spacing of the embossing can be adjusted as needed.

3. Punching operation: Use the punching die to punch out the required holes on the cylinder. The size and position of the punching can be precisely controlled by programming or manual adjustment.

4. Flange flanging: Use the flanging die to fold the edge of the cylinder into a flange shape for connection with other components. The angle and size of the flanging can be adjusted according to different flange standards.

We are grateful for your support and trust along the way. We are honored by your cooperation every time, and we will live up to your trust and provide you with a more excellent experience.

We can also help you with all your equipment packaging needs. Whether you need split packaging, certified materials or general packaging advice, our team of experts can help you. We understand that every business is different, so we tailor our services to your needs. Our goal is to make your life easier by meeting all your packaging needs so that you can focus on running your business.

As a professional mechanical equipment manufacturer, our company is a private technology innovation enterprise integrating independent research and development, design and manufacturing, installation and commissioning, and training.

Our R&D team has 10 people, whose members cover multiple professional fields such as mechanical engineering, electronic information, and materials science, and have the ability to deal with different technical problems.

Our equipment is widely used in aerospace, energy, ventilation,hardware and furniture, tableware, medicine, electricity, packaging,construction,automobile and other industries and fields.

Q: When shipping, what kind of packing?

A: We use standard export packing.

Q: What are your delivery terms?

A: EXW, FOB, CFR, CIF.

Q: What's your delivery time?

A: Generally speaking, it takes 30 to 60 days after receiving your advance payment. The specific delivery time depends on the item and quantity of your order.

Q: Can you make it as required?

A: Yes, we can produce according to your samples or technical drawings. We can make molds and fixtures.

Q: Do you have professional engineers?

A: Yes.we have professional engineers and designers.

Q: Can you provide customzied machines?

A:Yes, we can design and manufacture according to your specific requirements.