Automatic Hydraulic Flanging Machine for Secondary Drawing is a special equipment that combines hydraulic transmission and automatic control technology. It is mainly used for secondary drawing and flanging of metal sheets. The equipment uses the high-pressure power provided by the hydraulic system and cooperates with the automatic control system to achieve precise flanging of metal sheets. It is particularly suitable for the production of metal products that require complex flanging processes.

1. High-precision hydraulic transmission system

Adopting high-precision hydraulic proportional valve and servo motor drive, the pressure output is stable and the stroke control is precise to ensure the consistency and accuracy of flanging processing.

The hydraulic system has a wide pressure range and can meet the flanging requirements of metal sheets of different materials (such as stainless steel, carbon steel, aluminum alloy) and thicknesses (such as 1.5-4 mm).

2. Automatic control system

The equipment is equipped with a PLC control system and a human-computer interaction interface, supports parametric programming and process storage, and can quickly switch the processing mode of different products.

Support linkage with loading and unloading devices and detection equipment to achieve full-process automated production, reduce manual intervention, and improve production efficiency.

3. Multifunctional flanging processing capability

It can complete various processes such as flashing, chamfering, pressing, curling, hemming, pressing concave and convex ribs, etc., which is suitable for the complex flanging requirements of round metal products.

The flanging angle and width can be customized (such as flanging width 7mm to 25mm) to meet the design requirements of different products.

4. High-efficiency and energy-saving design

Energy-saving hydraulic pumps and motors (such as main motor 4-2.2KW, oil pump motor 2.2KW) are adopted, and the energy consumption is reduced by more than 30% compared with traditional equipment.

The hydraulic system is optimized to reduce oil temperature rise and energy loss, and extend the service life of the equipment.

5. Strong safety and reliability

The equipment is equipped with multiple safety protection devices (such as safety light curtains, emergency stop buttons, overload protection) to ensure the safety of operators and equipment.

The hydraulic system adopts a sealed design to prevent oil leakage and pollution, which meets environmental protection requirements.

1. Automobile manufacturing industry

It is used for flanging processing of automobile fuel tanks, exhaust pipes, doors and other parts to improve the sealing and strength of parts.

2. Home appliance manufacturing industry

Applicable to the flanging of the outer shell of refrigerators, washing machines and other products to enhance the beauty and durability of the products.

3. Aerospace field

Applicable to the flanging of high-precision parts such as aircraft fuel tanks and pipe connectors to meet strict process requirements.

4. Building decoration industry

Applicable to the flanging of metal doors, windows, curtain walls and other parts to enhance the decorative effect and structural strength.

5. Pipeline and container manufacturing

Applicable to processes such as flanging of pipeline ends and forming of pressure vessel heads to ensure the sealing and safety of the products.

1. Daily cleaning

After each use, clean the oil and metal chips on the surface of the equipment to keep the equipment clean.

Check the oil level and oil quality of the hydraulic system regularly and replace the hydraulic oil in time (it is recommended to replace it every six months to one year).

2. Hydraulic system maintenance

Regularly check the seals and pipe connections of the hydraulic system to prevent oil leakage.

Clean the hydraulic oil tank and filter element to ensure that the hydraulic oil is clean and free of impurities.

3. Mold maintenance

Clean the mold in time after use to remove oil and metal chips on the surface to prevent rust or damage.

Lubricate and maintain the mold regularly to extend the service life of the mold.

4. Electrical system inspection

Regularly check the wiring and components of the electrical system to ensure that the electrical system is safe and reliable.

Prevent the electrical system from moisture or water ingress to avoid short circuits or electric shock accidents.

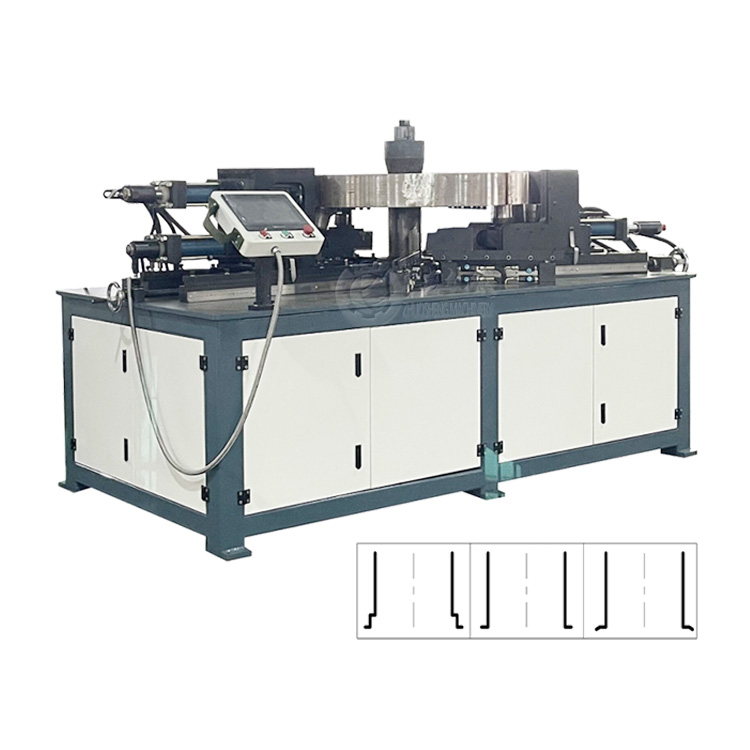

Structural Features:

- Sturdy body: In order to withstand the strong pressure generated by the hydraulic system and ensure stability during the processing, the body is usually welded with heavy steel, which has high strength and rigidity, and can effectively reduce the vibration and deformation of the equipment during operation.

- High-precision mold: The mold is a key component that determines the quality of the flanging. For the operation of secondary drawing and pressing S edge, high-precision and high-hardness molds are required. The size and shape of these molds are precisely designed and processed to perfectly match the size and shape of the stainless steel cylinder to ensure the accuracy and consistency of the flanging.

- Automatic control system: Generally equipped with advanced automatic control systems, such as PLC controllers or CNC systems. Operators can input processing parameters such as pressure, speed, stroke, etc. through the touch screen or control panel. The control system will automatically control the action of the hydraulic system and mechanical components according to these parameters to achieve automated processing and improve production efficiency and processing accuracy.

- Positioning device: In order to ensure the accurate position of the stainless steel cylinder during processing, the equipment is usually equipped with a positioning device. These positioning devices can quickly and accurately fix the cylinder on the workbench and keep its position unchanged during processing, thereby ensuring the accuracy and quality of the flanging.

Advantages:

- High processing efficiency: The automated operation method can greatly shorten the processing time and improve production efficiency. Compared with traditional manual flanging or mechanical flanging, the automatic hydraulic flanging machine can complete a large amount of flanging work in a short time.

- Good flanging quality: The stable pressure provided by the hydraulic system and the cooperation of high-precision molds can ensure the dimensional accuracy, shape accuracy and surface quality of the flanging, so that the stainless steel cylinder after flanging has good sealing and strength.

- Easy to operate: The operator only needs simple training to master the operation method of the equipment. The control system can easily adjust the processing parameters to adapt to the flanging processing of stainless steel cylinders of different specifications and requirements.

- Strong adaptability: It can be applied to the flanging processing of stainless steel cylinders of different diameters, thicknesses and lengths, with strong adaptability and versatility.

| Place of Origin: | Guangdong, China |

| Machine Type: | Cold Forging Machine |

| Weight (KG): | 3500 |

| Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided |

| Marketing Type: | Ordinary Product |

| Warranty of core components: | 1 Year |

| Core Components: | PLC, Engine, Bearing, Gearbox, Motor, Gear, Pump |

| Warranty: | 2 years |

| Key Selling Points: | Easy to Operate |

| Applicable Industries: | Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Other, Ventilation equipment manufacturer |

| Showroom Location: | None |

| Brand Name: | zhuosheng |

| Condition: | New |

| Power source type: | Ac 380V three-phase four-wire 50-60Hz |

| Equipment power: | 15kw |

| Equipment specification: | 2600x2000x1700(mm) |

| Workpiece diameter: | 250-1300(mm) |

| The thickness of the workpiece: | 0.6-4(mm) |

| The control mode: | PLC touch screen |

| Scope of application: | Round cylindrical hardware sheet metal processing |

| Number of punching: | 0-100 can be set |

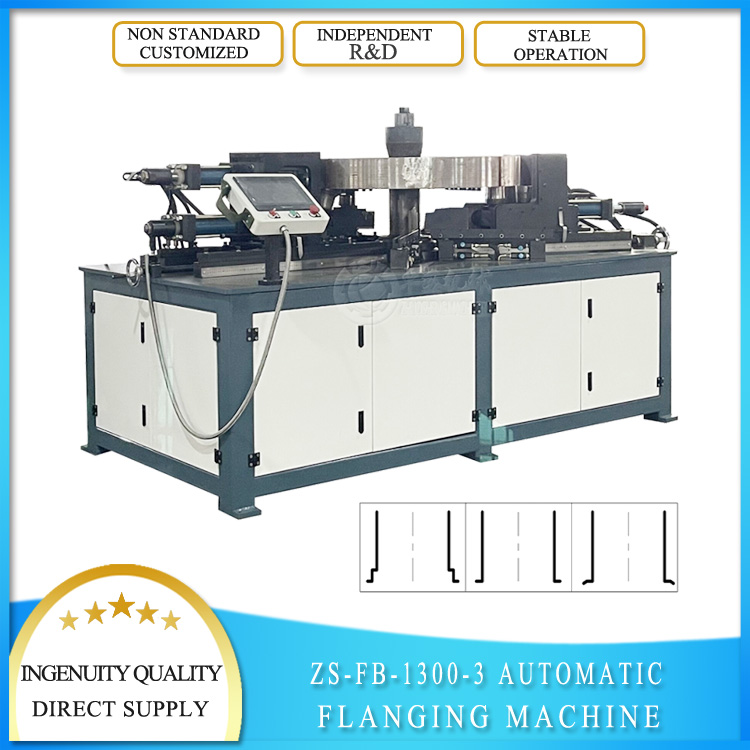

1. Non-standard customization: meet personalized technical requirements.

2. Samples and drawings: professional R&D team design.

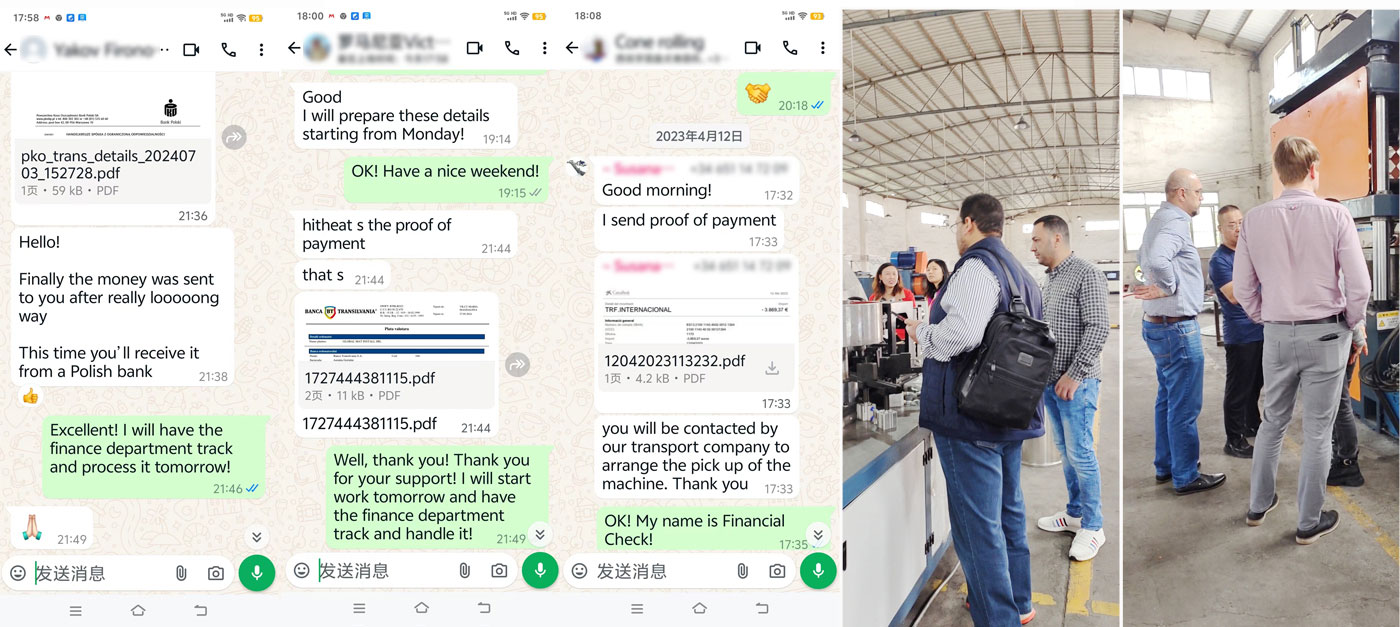

3. Flexible payment: T/T, LC, international bank.

4. Video factory inspection: can be scheduled.

5.Experienced professional sales service team.

6. Visual production process.

1. Provide circuit diagrams, maintenance manuals,full-course teaching videos and other materials required.

2. Full-time after-sales service, cooperate with customers to inspect, install and test.

3. Quick response: respond within 24 hours if there are any problems with the customers use.

- Pressure vessel manufacturing: In the production of pressure vessels, the quality of the flanging of stainless steel cylinders is directly related to the sealing and safety of the container. The secondary drawing and pressing S-side automatic hydraulic flanging machine can accurately flanging the cylindrical parts of pressure vessels to improve the quality and reliability of pressure vessels.

- Pipeline connection: In the pipeline system, the connection parts of stainless steel pipes need to be flanging to install flanges or other connectors. The equipment can perform efficient flanging of stainless steel pipes to meet the requirements of pipeline connection.

- Mechanical manufacturing: In some mechanical products, such as fans and pumps, stainless steel cylinder parts are also used. The flanging of these parts requires high precision and high quality. The secondary drawing and pressing S-side automatic hydraulic flanging machine can meet the requirements of stainless steel cylinder flanging in the field of mechanical manufacturing.

- Vibrating screen shell production: It can be used for vibrating screen shells. In the manufacture of vibrating screens, stainless steel cylinders as shells need to have good sealing and strength to prevent material leakage and ensure the stable operation of the equipment. The flanging machine can perform accurate secondary drawing and pressing S-edge processing on stainless steel cylinders, provide high-quality flanging for the vibrating screen shell, and ensure the sealing and structural strength of the shell.

Hydraulic drive system:

The equipment relies on the hydraulic system to provide strong and stable power. The hydraulic pump pressurizes the hydraulic oil and delivers it to the actuators such as hydraulic cylinders or hydraulic motors to push the flanging tool or mold to move. For example, the piston rod of the hydraulic cylinder extends, driving the flanging mold to apply pressure to the stainless steel cylinder, causing it to deform and complete the flanging operation.

Secondary drawing and pressing S edge process:

For stainless steel cylinders that have been drawn once, the machine can perform secondary processing. Secondary drawing is to further adjust the shape and size of the edge of the cylinder on the basis of the first drawing, so that it is more precise and meets the requirements. Pressing S edge is to press the edge of the cylinder into a special S-shaped shape through a specific mold and pressure. This shape of edge usually has better sealing, strength and aesthetics.

We are grateful for your support and trust along the way. We are honored by your cooperation every time, and we will live up to your trust and provide you with a more excellent experience.

We can also help you with all your equipment packaging needs. Whether you need split packaging, certified materials or general packaging advice, our team of experts can help you. We understand that every business is different, so we tailor our services to your needs. Our goal is to make your life easier by meeting all your packaging needs so that you can focus on running your business.

As a professional mechanical equipment manufacturer, our company is a private technology innovation enterprise integrating independent research and development, design and manufacturing, installation and commissioning, and training.

Our R&D team has 10 people, whose members cover multiple professional fields such as mechanical engineering, electronic information, and materials science, and have the ability to deal with different technical problems.

Our equipment is widely used in aerospace, energy, ventilation,hardware and furniture, tableware, medicine, electricity, packaging,construction,automobile and other industries and fields.

Q: When shipping, what kind of packing?

A: We use standard export packing.

Q: What are your delivery terms?

A: EXW, FOB, CFR, CIF.

Q: What's your delivery time?

A: Generally speaking, it takes 30 to 60 days after receiving your advance payment. The specific delivery time depends on the item and quantity of your order.

Q: Can you make it as required?

A: Yes, we can produce according to your samples or technical drawings. We can make molds and fixtures.

Q: Do you have professional engineers?

A: Yes.we have professional engineers and designers.

Q: Can you provide customzied machines?

A:Yes, we can design and manufacture according to your specific requirements.