Stainless Steel Round Table Top Trimming Machine is an automated equipment designed for metal table top edge trimming. Through the combination of CNC system and modular tools, it can realize the precise trimming, chamfering, polishing and other processes of round table tops made of metal materials such as stainless steel and aluminum alloy. Its core value lies in replacing traditional manual operations, solving pain points such as low efficiency, poor precision, and many edge burrs. It is widely used in furniture manufacturing, commercial catering, outdoor facilities, high-end engineering and other fields. It is a key tool for upgrading the efficiency and quality of the metal table top processing industry.

CNC system (CNC):

Supports CAD drawing import and automatic generation of processing paths with an error of ≤±0.1mm.

Equipped with PLC (programmable logic controller) and touch screen operation interface, supports multi-language switching (Chinese, English, German, French, etc.).

Modular tool design:

The tool library includes chamfering knives, polishing wheels, trimming knives, etc., supports one-button switching, and the speed is adjustable (0-8000 rpm).

The tool material is carbide, suitable for different metal materials (such as 304 stainless steel, 6061 aluminum alloy).

Positioning and clamping system:

Pneumatic clamping device, suitable for round table top diameter 300mm-2000mm, supports laser positioning assistance.

The clamping pressure is adjustable (0.5-1.2MPa) to avoid table top deformation.

High-precision trimming:

Edge straightness ≤0.05mm, chamfer angle accuracy ±1°, supports R angle (rounded corner), C angle (bevel) and other shapes.

Automated polishing:

Rough polishing + fine polishing two-stage process, surface roughness Ra ≤0.8μm, to achieve a mirror effect.

Dust prevention and noise reduction:

Fully enclosed processing cabin, equipped with industrial-grade dust removal system, dust collection rate ≥99%.

Operating noise ≤75dB, in line with occupational health standards (OSHA).

Energy saving and efficiency:

The main motor power is 3kW, and the energy consumption is reduced by 30% compared with traditional models.

The processing cycle of a single countertop is ≤3 minutes, and the daily production capacity reaches 200-300 pieces.

Scenario 1: Mass production of high-end stainless steel dining tables

Problem: Manual trimming is inefficient, edge burrs are easy to scratch users, and the polishing consistency is poor.

Solution:

Automated processing by trimming machine, 100% edge burr removal rate, and 90% polishing consistency improvement.

Supports processing of countertops with a diameter of 300mm-2000mm, suitable for home, commercial, hotel and other scenarios.

Scenario 2: Customized metal countertop processing

Problem: Customers have diverse requirements for edge shapes (such as R angles and wavy shapes), and manual adjustments are time-consuming.

Solution:

The CNC system supports more than 10 preset edge shapes, quickly switches processing modes, and customized production efficiency is increased by 50%.

Scenario 1: Fast delivery of chain restaurant countertops

Problem: Restaurants require a short delivery cycle for countertops, and traditional processes require multiple processes.

Solution:

The trimming machine integrates trimming, chamfering and polishing functions. A single device completes the entire process, shortening the delivery cycle by 70%.

Scenario 2: Rust-proof treatment of outdoor dining countertops

Problem: Outdoor countertops are easily corroded by rainwater, and edge rust affects the appearance and service life.

Solution:

The edges are smooth and burr-free after trimming, and the corrosion resistance of the countertop is increased by 3 times with the anti-rust coating process.

Scenario 1: Processing of stainless steel tables and chairs in parks and scenic spots

Problem: Outdoor tables and chairs need to be exposed to the natural environment for a long time, and improper edge treatment can easily cause the coating to peel off.

Solution:

The edges are smoothly transitioned after trimming, the coating adhesion is increased by 40%, and the outdoor service life is extended to more than 10 years.

Scenario 2: Processing of special-shaped outdoor countertops

Problem: Manual trimming of curved and wavy countertops is difficult and inefficient.

Solution:

The CNC system supports 3D curved surface processing, and the trimming efficiency of special-shaped countertops is increased by 80%, and the scrap rate is reduced to less than 1%.

Scenario 1: Customization of metal countertops in hotel lobbies

Problem: The hotel has high requirements for the edge details of the countertops, and manual processing is difficult to meet the mirror polishing requirements.

Solution:

The surface roughness Ra≤0.8μm after the trimming machine fine polishing process is suitable for high-end scenes such as hotels and clubs.

Scenario 2: Processing of metal guardrail countertops on subway platforms

Problem: The guardrail countertop needs to be anti-collision and anti-rust, and the edge processing needs to take into account both safety and beauty.

Solution:

The edge R angle transition after trimming machine processing can avoid pedestrian bumps and improve rust resistance.

Tool cleaning:

After daily processing, wipe the metal chips on the surface of the tool with a clean cloth to avoid scratches caused by residues.

Check the tool wear every week, and the chamfering knife and polishing wheel need to be replaced if the wear exceeds 2mm.

Guide lubrication:

Apply special grease to the X/Y/Z axis guide rails every day to ensure smooth operation.

Check the straightness of the guide rail every month. If the deviation exceeds 0.1mm, it needs to be adjusted.

Dust removal system maintenance:

Clean the dust box every day to prevent dust accumulation from affecting suction.

Check the filter element every month. If the blockage rate exceeds 50%, it needs to be replaced.

Electrical system detection:

Check whether the wiring of electrical components such as PLC, servo motor, and sensor is loose.

Use an insulation tester to detect the insulation of the line. If the resistance is lower than 1MΩ, it needs to be repaired.

Mechanical structure calibration:

Calibrate the pneumatic pressure of the clamping device to ensure the positioning accuracy of the table.

Check the accuracy of the laser positioning system. If the deviation exceeds 0.2mm, it needs to be recalibrated.

Moisture-proof treatment:

When the equipment is out of use for a long time, it needs to be coated with anti-rust oil and covered with moisture-proof film.

Storage environment humidity ≤60%, temperature 5℃-35℃.

Regular trial run:

Start the equipment and run it without load for 10 minutes every 3 months to avoid rust on mechanical parts.

Q1: Does the equipment support special-shaped table processing?

A: Yes. By importing 3D drawings through the CNC system, special-shaped countertops such as arcs and waves can be processed with an accuracy of ≤±0.1mm.

Q2: What is the maximum processing table diameter?

A: The standard model supports a 2000mm diameter table, and the customized model can be expanded to 3000mm.

Q3: What is the energy consumption of the equipment?

A: The main motor power is 3kW, and the average daily power consumption is about 24 degrees for 8 hours of work, which is 30% energy-saving than traditional models.

Q4: What is the surface roughness after polishing?

A: The surface roughness after fine polishing is Ra≤0.8μm, achieving a mirror effect.

Q5: Can it be integrated with existing production lines?

A: It supports communication protocols such as Modbus and TCP/IP, and can be connected to the MES system to realize automated assembly line production.

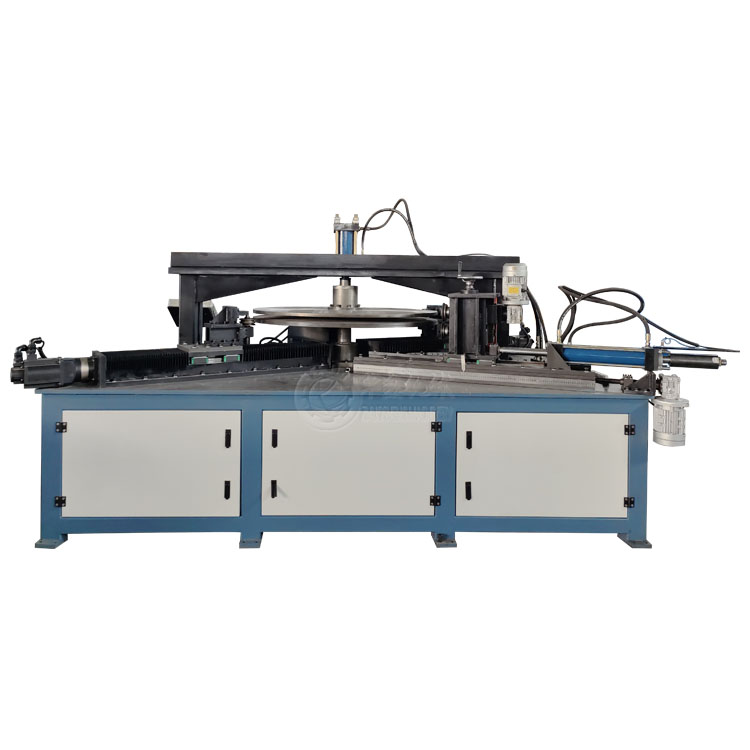

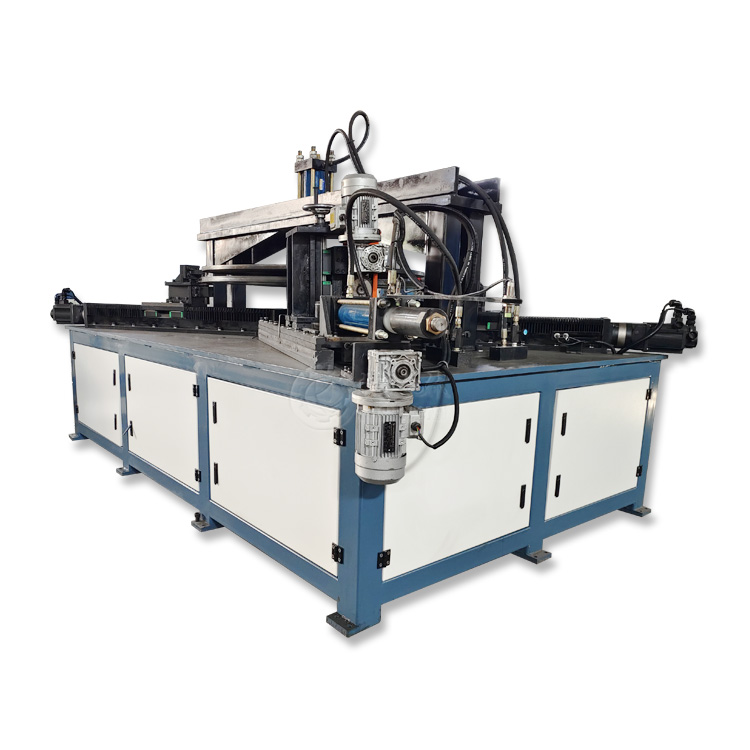

Structural Features:

1. Sturdy body: In order to withstand the strong pressure generated by the hydraulic system and ensure stability during processing, the body is usually welded with heavy steel, which has high strength and rigidity, and can effectively reduce the vibration and deformation of the equipment during operation.

2. High-precision mold system: The material of the mold is usually high-strength and high-hardness alloy steel, which is precision-processed and heat-treated to ensure its dimensional accuracy and durability. The installation and replacement of the mold is convenient and quick, and can meet the processing needs of stainless steel disc desktops of different specifications.

3. Automated operation platform: Equipped with an easy-to-operate automated operation platform, the operator can intuitively understand the operating status and processing progress of the equipment. Various control buttons and indicator lights are set on the platform to facilitate parameter adjustment and troubleshooting.

4. Safety protection device: In order to ensure the safety of the operator, the equipment is equipped with complete safety protection devices, such as protective covers, safety doors, emergency stop buttons, etc. During the operation of the equipment, these devices can effectively prevent accidents.

Advantages:

1. Efficient processing: The automated operation mode and the powerful power of the hydraulic system enable the equipment to quickly and efficiently complete processing tasks such as trimming, curling and flanging, greatly improving production efficiency.

2. High-precision processing: The high precision of the mold and the precise control of the automated control system ensure the accuracy and consistency of the processing, so that the processed stainless steel disc table has good appearance quality and dimensional accuracy.

3. Versatility: The equipment can perform various operations such as trimming, curling and flanging according to different processing requirements, and has strong versatility and adaptability.

4. Convenient operation: The automated operating platform and easy-to-understand control system allow operators to easily master the operation methods of the equipment, reducing training costs and operating difficulties.

5. Safe and reliable: The perfect safety protection device and stable fuselage structure ensure the safe and reliable operation of the equipment and reduce the risk of accidents.

| Origin: | Guangdong, China |

| Machine type: | cold forging machine |

| Weight (KG): | 3600 |

| Video factory inspection: | provided |

| Machine test report: | provided |

| Sales type: | general products |

| Core component warranty: | 1 year |

| Core components: | PLC, gearbox, motor, gear, pump |

| Warranty: | 1 year |

| Main selling point: | easy to operate |

| Applicable industries: | manufacturing plants, retail, construction projects, other |

| Showroom location: | no |

| Condition: | brand new |

| Power type: Power type: | 380V three-phase five-wire. |

| Equipment specifications (mm): | 2100x2500x2600 (length, width and height) |

| Processing range diameter: | 600-1500mm |

| Processing thickness: | 0.5-1.5mm |

| Equipment power: | 17kw |

| Control mode: | CNC |

| Drive mode: | servo motor |

| Equipment function: | squaring, trimming, curling |

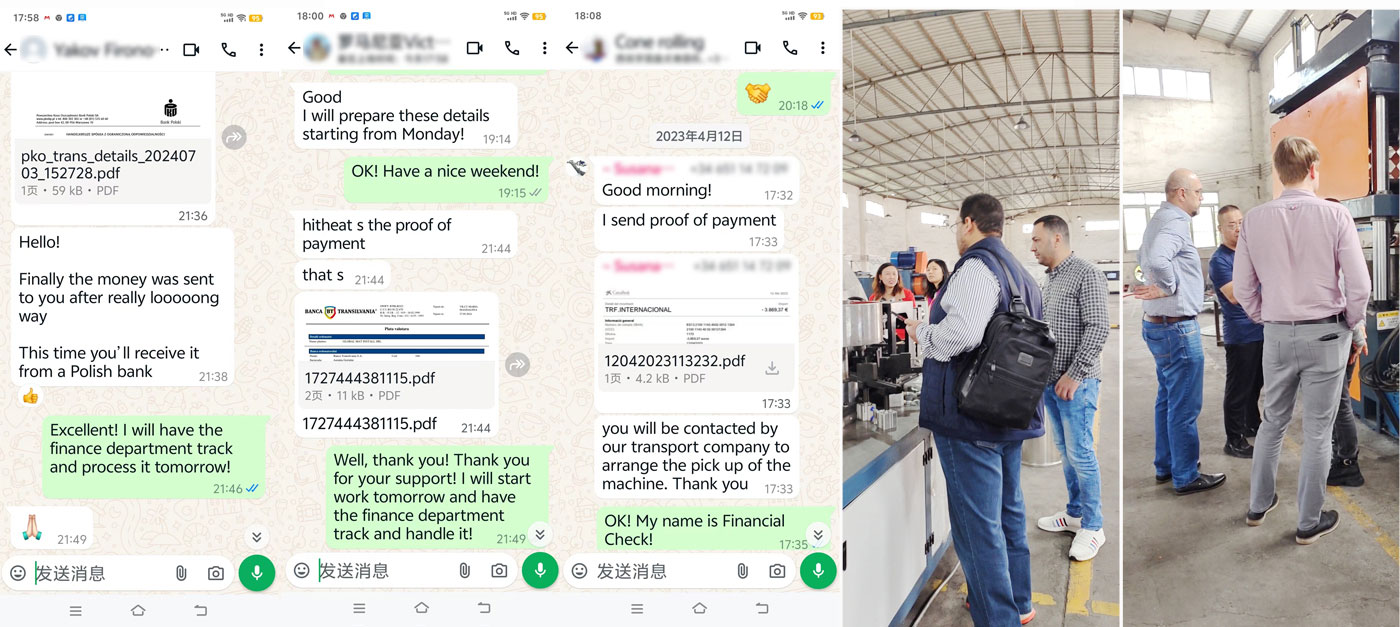

1. Non-standard customization: meet personalized technical requirements.

2. Samples and drawings: professional R&D team design.

3. Flexible payment: T/T, LC, international bank.

4. Video factory inspection: can be scheduled.

5.Experienced professional sales service team.

6. Visual production process.

1. Provide circuit diagrams, maintenance manuals,full-course teaching videos and other materials required.

2. Full-time after-sales service, cooperate with customers to inspect, install and test.

3. Quick response: respond within 24 hours if there are any problems with the customers use.

1. Furniture manufacturing: In stainless steel furniture manufacturing, disc desktops are one of the common components. The automatic hydraulic stainless steel disc tabletop trimming, curling and flanging machine can provide furniture manufacturers with high-quality tabletop processing solutions to improve the appearance quality and durability of the products.

2. Kitchenware manufacturing: The round countertops, baking trays and other parts in stainless steel kitchenware can also be processed using this equipment. Through trimming, curling and flanging, the kitchenware can be made more beautiful and practical, and the market competitiveness of the product can be improved.

3. Decoration engineering: In indoor and outdoor decoration projects, stainless steel disc tabletops can be used as decorative elements. The equipment can provide customized processing services for decoration projects to meet different design requirements.

4. Industrial manufacturing: In some industrial fields, such as machinery manufacturing and electronic equipment manufacturing, stainless steel disc tabletops are also used. The automatic hydraulic stainless steel disc tabletop trimming, curling and flanging machine can provide high-precision processing services for these industries to ensure the quality and performance of the products.

1. Hydraulic drive: The equipment uses the hydraulic system to provide powerful and stable power. The hydraulic oil is pressurized by the hydraulic pump and then delivered to the hydraulic cylinder to push the actuator to move. During the trimming, curling and flanging process, the precise control of the hydraulic cylinder ensures the accuracy and strength of the processing.

2. Mold function: Equipped with special molds, which can be replaced according to different processing requirements. The design and manufacturing accuracy of the mold directly affect the processing quality. For the trimming of stainless steel disc desktops, the mold can remove burrs and uneven parts on the edge; the curling mold curls the edge of the disc into a specific shape; the flanging mold can fold the edge up or down to form a specific edge structure.

3. Automated control: Use advanced automated control systems, such as PLC controllers or CNC systems. Operators can input processing parameters such as pressure, speed, stroke, etc. through the touch screen or control panel. The control system will automatically control the action of the hydraulic system and mechanical components according to these parameters to achieve automated processing and improve production efficiency and processing accuracy.

We are grateful for your support and trust along the way. We are honored by your cooperation every time, and we will live up to your trust and provide you with a more excellent experience.

We can also help you with all your equipment packaging needs. Whether you need split packaging, certified materials or general packaging advice, our team of experts can help you. We understand that every business is different, so we tailor our services to your needs. Our goal is to make your life easier by meeting all your packaging needs so that you can focus on running your business.

As a professional mechanical equipment manufacturer, our company is a private technology innovation enterprise integrating independent research and development, design and manufacturing, installation and commissioning, and training.

Our R&D team has 10 people, whose members cover multiple professional fields such as mechanical engineering, electronic information, and materials science, and have the ability to deal with different technical problems.

Our equipment is widely used in aerospace, energy, ventilation,hardware and furniture, tableware, medicine, electricity, packaging,construction,automobile and other industries and fields.

Q: When shipping, what kind of packing?

A: We use standard export packing.

Q: What are your delivery terms?

A: EXW, FOB, CFR, CIF.

Q: What's your delivery time?

A: Generally speaking, it takes 30 to 60 days after receiving your advance payment. The specific delivery time depends on the item and quantity of your order.

Q: Can you make it as required?

A: Yes, we can produce according to your samples or technical drawings. We can make molds and fixtures.

Q: Do you have professional engineers?

A: Yes.we have professional engineers and designers.

Q: Can you provide customzied machines?

A:Yes, we can design and manufacture according to your specific requirements.