Six-Group Disc-Type Automatic Polishing Machine is a highly automated polishing solution. With a unique six-group disc structure as its core, it achieves efficient and precise polishing operations through automated control. This equipment has important application value in the field of end-end processing, and can significantly improve the surface quality of the end-end, meeting the strict requirements of different industries for end-end surface treatment. Its working principle is to use the synergistic effect of six discs to perform multi-stage polishing on the end-end, gradually improving the surface finish from rough polishing to fine polishing, while using the automated control system to ensure the stability and consistency of the polishing process.

1. Exquisite structure

The Six-Group Disc-Type Automatic Polishing Machine adopts a multi-disc combination structure, with six discs arranged in sequence to form an organic whole. This design not only allows the polishing process to be carried out in stages, but also allows for flexible adjustment according to the shape of the head. The size and arrangement of the discs are carefully designed to better fit the curved shape of the head. Whether it is a hemispherical or elliptical head, the disc can effectively polish the entire surface by adjusting the angle and position, reducing the polishing dead angle, and ensuring that the surface of the head is finely processed without omission. Its overall structure is compact, the layout is reasonable, the footprint is small, and it is easy to install and maintain, which meets the requirements of modern industrial production for equipment space utilization and convenient operation.

2. High level of automation

The Six-Group Disc-Type Automatic Polishing Machine has a very high degree of automation and can automatically complete the entire polishing process. From the clamping of the head, the control of the polishing process to the final unloading, basically no large amount of manual intervention is required. The operator only needs to set the polishing parameters at the beginning, such as the speed of each disc, polishing time, feed rate, etc., and the machine can work accurately according to the set program. Its control system adopts advanced industrial automation technology, has high stability and reliability, can monitor various parameters in the polishing process in real time, and automatically adjust as needed to ensure the smooth progress of the polishing process. This highly automated operation method not only improves production efficiency, but also reduces the intensity of manual labor and reduces the impact of human factors on polishing quality.

3. High polishing accuracy

The Six-Group Disc-Type Automatic Polishing Machine can achieve high-precision polishing of the head surface through precise mechanical structure and control system. It can control the roughness of the head surface within a very low range, so that the head can achieve a mirror-like smooth effect. Its high level of polishing accuracy is due to advanced mechanical manufacturing technology and high-precision control system. During the polishing process, the speed, feed rate and other parameters of each disc can be accurately controlled to ensure that the contact between the polishing material and the head surface is uniform and moderate. At the same time, the equipment is also equipped with high-precision sensors and monitoring systems, which can provide real-time feedback on the surface quality during the polishing process, so as to adjust the polishing parameters in time and further improve the polishing accuracy. This high-precision polishing capability enables it to meet various high-demand head processing tasks and provide users with high-quality products.

4. Stable polishing quality

The automatic polishing function of the Six-Group Disc-Type Automatic Polishing Machine ensures that the polishing process and parameters of each head are consistent, thereby ensuring the stability of the polishing quality. Since the entire polishing process is completed automatically by the machine and is not affected by the differences in manual operation, there will be no uneven surface quality of the head due to different technical levels of operators. Its stable polishing quality provides users with reliable production guarantees and helps to improve the overall quality and market competitiveness of the product. No matter how many heads are produced in batches, the surface of each head can meet the same high quality standards, saving users time and cost for quality inspection and rework.

5. Flexible motor and speed adjustment

The six discs of the Six-Group Disc-Type Automatic Polishing Machine are usually driven by multiple motors, and the motor power varies according to the size of the disc and the required polishing intensity. This flexible motor configuration enables the machine to adapt to the polishing needs of heads of different sizes and materials. At the same time, the speed of the disc can also be adjusted to adapt to different polishing stages and head materials. In the rough polishing stage, the disc speed may be low to better remove larger defects on the head surface; while in the fine polishing stage, the speed will be increased to achieve a higher surface finish. This flexible speed adjustment function provides users with more operating options, and can optimize the polishing effect according to actual production needs and improve production efficiency.

6. Efficient feeding system

The feeding system of the Six-Group Disc-Type Automatic Polishing Machine is a key component to ensure the uniformity and efficiency of polishing. The feeding system parameters include feed speed, feed amount, etc. The reasonable setting of these parameters can ensure that the contact mode and force between the disc and the head surface are just right. During the polishing process, the feeding system can accurately control the relative movement of the disc and the head according to the set parameters, so that the polishing material acts evenly on the head surface to avoid excessive or insufficient local polishing. At the same time, the efficient feeding system can also improve polishing efficiency, shorten production cycle, and bring higher production benefits to users.

| Origin: | Guangdong, China |

| Condition: | Brand new |

| Shipment inspection video: | Provided |

| Mechanical test report: | Provided |

| Marketing type: | General product |

| Core component warranty: | 1 year |

| Core components: | PLC, motor |

| Power (kW): | 38 |

| Weight (KG): | 10000 |

| Main selling point: | Easy to operate |

| Warranty: | 1 year |

| Applicable industry: | Manufacturing plant |

| Showroom location: | No |

| Brand name: | Zhuosheng |

| Article number: | 1月16日 |

| Model: | ZS-YP-2500 |

| Type: | Automatic polishing machine |

| Working principle: | Disc polishing machine |

| Power type: | AC power supply |

| Rated input power: | 38000 (W) |

| Power: | 38 (KW) |

| Polishing wheel diameter: | 450 (mm) |

| Polishing spindle thread: | 2 |

| After-sales service provided: | Video technical support |

1. Non-standard customization: meet personalized technical requirements.

2. Samples and drawings: professional R&D team design.

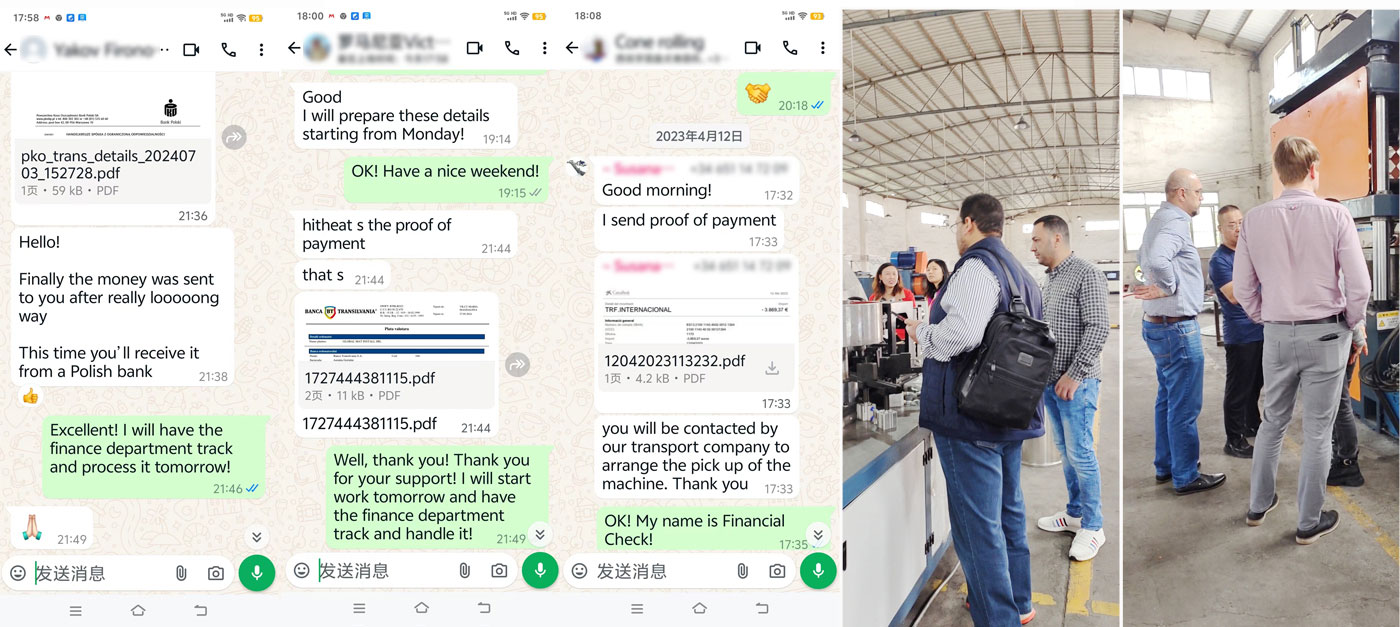

3. Flexible payment: T/T, LC, international bank.

4. Video factory inspection: can be scheduled.

5.Experienced professional sales service team.

6. Visual production process.

1. Provide circuit diagrams, maintenance manuals,full-course teaching videos and other materials required.

2. Full-time after-sales service, cooperate with customers to inspect, install and test.

3. Quick response: respond within 24 hours if there are any problems with the customers use.

1. Processing of pressure vessel heads

In the field of pressure vessel manufacturing, Six-Group Disc-Type Automatic Polishing Machine is widely used in head processing. The surface quality of pressure vessel heads is directly related to the safety and reliability of the equipment. The equipment can polish the heads efficiently and accurately, remove surface defects such as rust and scratches, and make the head surface meet the specified finish standard, thereby improving the overall quality of the pressure vessel. At the same time, it can also be flexibly adjusted according to different head sizes and materials to meet the processing needs of pressure vessel heads of various specifications.

2. Polishing of boiler heads

For the boiler industry, the surface quality of the heads is also crucial. Six-Group Disc-Type Automatic Polishing Machine can perform high-quality polishing on boiler heads to improve the corrosion resistance and thermal conductivity of the heads. Its automated polishing function ensures the stability of the polishing quality, reduces the quality fluctuations that may be caused by manual operation, and provides boiler manufacturers with a reliable head surface treatment solution, which helps to improve the service life and operating efficiency of the boiler.

3. Processing of chemical equipment heads

In the manufacturing of chemical equipment, the surface treatment of the heads needs to meet strict anti-corrosion and sealing requirements. Six-Group Disc-Type Automatic Polishing Machine can perform fine polishing on the heads of chemical equipment, remove burrs and impurities on the surface, improve the surface finish of the heads, and thus enhance their anti-corrosion and sealing properties. Its high-precision polishing ability can meet the high standards of chemical equipment for the surface quality of the heads, and provide protection for the safe operation of chemical equipment.

4. Head processing of food processing equipment

The heads of food processing equipment need to meet strict hygiene standards. Six-Group Disc-Type Automatic Polishing Machine can perform efficient and hygienic polishing on the heads of food processing equipment, making the surface of the heads smooth and without dead corners, which is easy to clean and disinfect. Its automated operation reduces manual contact, reduces the risk of contamination, ensures the hygienic safety of food processing equipment, and provides reliable head processing equipment for food processing companies.

5. Polishing of pharmaceutical equipment heads

Pharmaceutical equipment has extremely high requirements for the surface quality of the heads to prevent drug contamination and ensure drug quality. Six-Group Disc-Type Automatic Polishing Machine can perform high-precision polishing on the heads of pharmaceutical equipment, so that the surface of the heads can achieve a mirror-like finish, reducing the possibility of drug residues and microbial growth. Its stable polishing quality ensures that each head can meet the same high quality standards, providing reliable guarantee for the production of pharmaceutical equipment and meeting the strict requirements of the pharmaceutical industry.

6. Shipbuilding head processing

In the field of shipbuilding, Six-Group Disc-Type Automatic Polishing Machine is used for the processing of ship heads. The surface quality of ship heads is related to the corrosion resistance and sealing of the ship. The equipment can polish the ship heads efficiently and evenly, improve the surface finish of the heads, and enhance their corrosion resistance and sealing performance. Its flexible adjustment function can adapt to ship heads of different sizes and shapes, providing shipbuilding companies with an efficient head surface treatment equipment, which helps to improve the manufacturing quality and service life of ships.

We are grateful for your support and trust along the way. We are honored by your cooperation every time, and we will live up to your trust and provide you with a more excellent experience.

We can also help you with all your equipment packaging needs. Whether you need split packaging, certified materials or general packaging advice, our team of experts can help you. We understand that every business is different, so we tailor our services to your needs. Our goal is to make your life easier by meeting all your packaging needs so that you can focus on running your business.

As a professional mechanical equipment manufacturer, our company is a private technology innovation enterprise integrating independent research and development, design and manufacturing, installation and commissioning, and training.

Our R&D team has 10 people, whose members cover multiple professional fields such as mechanical engineering, electronic information, and materials science, and have the ability to deal with different technical problems.

Our equipment is widely used in aerospace, energy, ventilation,hardware and furniture, tableware, medicine, electricity, packaging,construction,automobile and other industries and fields.