2500-2 Heavy-Duty Double-Roller CNC Spinning Machine for Tank Heads

Focusing on Non-Standard Customization Zhuosheng Machinery's 2500-2 Double-Roller CNC Spinning Machine provides professional solutions to head manufacturing challenges

Industry Pain Points: Three Major Challenges in Head Manufacturing

In pressure vessels, chemical equipment, energy equipment, and other fields, heads are key components, and their manufacturing quality directly affects the performance of the entire machine. As a machinery manufacturer with many years of experience in the industry, we understand the challenges you face:

• Difficulty in Precision Control: Traditional processes struggle to guarantee the dimensional accuracy and surface quality of large heads.

• Efficiency Bottleneck: Long processing cycles for complex curved surfaces restrict overall production efficiency.

• Customization Difficulty: Standard equipment cannot meet the processing needs of special materials and irregular structures.

These pain points are precisely the initial motivation behind our development of the 2500-2 Double-Roller CNC Spinning Machine.

Solution: Three Core Technological Breakthroughs

1. Intelligent CNC System - Dual Guarantee of Precision and Efficiency: Utilizing a new generation of CNC system, the entire machining process is digitally controlled. Through intelligent programming, it can precisely perform machining of complex curved surfaces such as ellipses, butterflies, and hemispheres, achieving one-time forming and significantly improving product consistency and production efficiency.

2. Heavy-Duty Dual-Roller Structure - Stable and Reliable Performance Foundation: For the machining needs of large workpieces, the equipment adopts a reinforced body design and a dual-roller configuration. The two rollers can be controlled independently to achieve synchronous or asynchronous machining, ensuring excellent stability under heavy cutting conditions.

3. Fully Hydraulic Drive System - Perfect Balance of Power and Precision: The high-performance hydraulic system provides smooth and powerful spinning force, combined with precision servo control, enabling precise adjustment of machining parameters and easily handling machining requirements of different materials and thicknesses.

Zhuosheng's Strength: Professional Guarantee for Non-Standard Customization

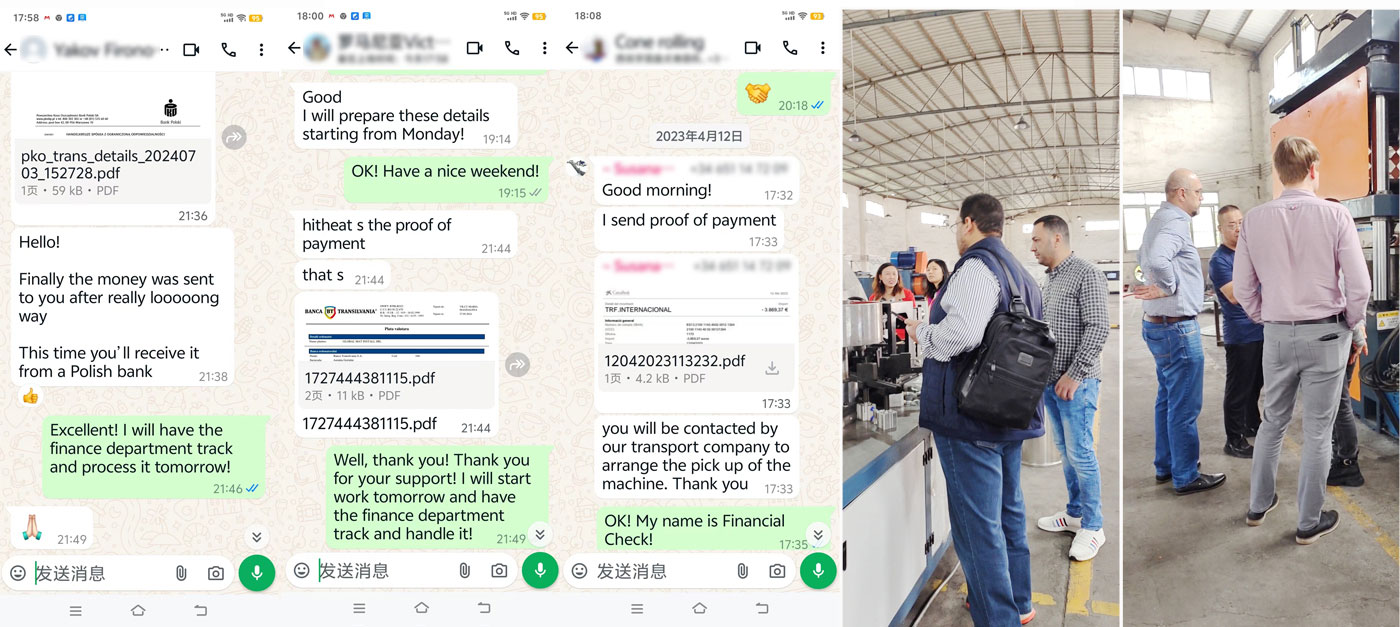

As one of China's leading manufacturers of non-standard machinery and equipment customization, Jiangmen Zhuosheng Machinery Co., Ltd. possesses the following core advantages:

• Professional Team: A technical team with over 20 years of experience in spinning equipment R&D

• Customization Capabilities: Deep customization of equipment parameters and functional configurations based on customer process requirements

• Full-Process Service: Comprehensive support from solution design and equipment commissioning to technical training. We have provided professional spinning solutions for end caps to numerous large equipment manufacturing enterprises. Our equipment is widely used in high-end manufacturing fields such as chemical containers, nuclear power equipment, and aerospace.

Cooperation Value: Helping Enterprises Enhance Core Competitiveness

Choosing the Zhuosheng 2500-2 CNC spinning machine will bring you:

●A new level of processing accuracy

●Significantly increased production efficiency

●Effective expansion of product types

●Optimized control of overall costs. We sincerely invite you to visit and inspect our facilities. We believe this CNC spinning machine, designed specifically to solve the challenges of end cap manufacturing, will bring innovation to your production.

Choose Zhuosheng Machinery, choose professionalism! Let's join hands and create a new chapter in manufacturing!

1. Non-standard customization: meet personalized technical requirements.

2. Samples and drawings: professional R&D team design.

3. Flexible payment: T/T, LC, international bank.

4. Video factory inspection: can be scheduled.

5.Experienced professional sales service team.

6. Visual production process.

1. Provide circuit diagrams, maintenance manuals,full-course teaching videos and other materials required.

2. Full-time after-sales service, cooperate with customers to inspect, install and test.

3. Quick response: respond within 24 hours if there are any problems with the customers use.

| Power supply type: | AC 380V three-phase four-wire (customizable for overseas markets) | Maximum Spinning Sheet Diameter: | 3000mm |

| Spindle speed: | 0-300 rpm | Spinning Thickness (Iron Plate): | 1-10mm |

| Air pressure: | 0.5-0.8 MPa | Spinning Thickness (Aluminum Plate): | 1-12mm |

| Spindle center height: | 1500 mm | Spinning Thickness (Stainless Steel Plate): | 1-5mm |

| Axial travel: | 1100 mm | Maximum Spinning Product Height: | 600mm |

| Axial travel: | 1250 mm | Pressure Power: | Hydraulic |

| Tail tip travel: | 1100 mm | Control System: | GGO/Keyuan/KND |

| Positioning accuracy: | 0.1 mm | Spinning Structure: | Horizontal |

| Automatic lubrication system: | AC220V 25W1 | Warranty Period: | 1 year |

| Installation Positions: | 2+2 positions | Drive Type: | Servo |

| Input Method: | Handwheel teaching/CAD drawing | Equipment Weight: | 24 tons |

| Equipment Dimensions: | 6000x4200x2600 (mm) | Die Mounting: | Connecting Flange |

We are grateful for your support and trust along the way. We are honored by your cooperation every time, and we will live up to your trust and provide you with a more excellent experience.

We can also help you with all your equipment packaging needs. Whether you need split packaging, certified materials or general packaging advice, our team of experts can help you. We understand that every business is different, so we tailor our services to your needs. Our goal is to make your life easier by meeting all your packaging needs so that you can focus on running your business.

As a professional mechanical equipment manufacturer, our company is a private technology innovation enterprise integrating independent research and development, design and manufacturing, installation and commissioning, and training.

Our R&D team has 10 people, whose members cover multiple professional fields such as mechanical engineering, electronic information, and materials science, and have the ability to deal with different technical problems.

Our equipment is widely used in aerospace, energy, ventilation,hardware and furniture, tableware, medicine, electricity, packaging,construction,automobile and other industries and fields.