Dry High-Speed Automatic Polishing Machine is an advanced surface treatment equipment in the field of metal processing. It uses high-speed rotating polishing tools to quickly and automatically polish the surface of metal workpieces without liquid cooling or lubricating media (dry method). This equipment abandons the use of liquid media in the traditional wet polishing process and provides an efficient, environmentally friendly and highly automated solution for the surface finishing of metal workpieces. It is one of the important equipment for modern metal processing enterprises to improve production efficiency and product quality.

1. Efficient polishing

The polishing head of the Dry High-Speed Automatic Polishing Machine is driven by a motor with an extremely high speed, usually up to thousands of revolutions per minute, which can quickly remove defects on the surface of metal workpieces. This high-speed rotating polishing method allows the tiny bumps and oxide layers on the surface of the workpiece to be quickly smoothed under the action of friction, greatly shortening the polishing time. Compared with traditional polishing equipment, it can significantly improve production efficiency and meet the high-efficiency requirements of modern industry for surface treatment of metal workpieces.

2. Dry operation

The equipment adopts dry processing without the use of coolant or lubricant. This not only avoids the subsequent steps of cleaning and removing liquid residues after polishing the workpiece, saving time and cost, but also reduces the generation of liquid waste, meets environmental protection requirements, and is a green and sustainable metal surface treatment process, providing metal processing companies with a more environmentally friendly production option.

3. High degree of automation

The Dry High-Speed Automatic Polishing Machine is equipped with an automated loading and unloading system. The workpiece is automatically fed into the polishing area through a conveyor belt or a robotic arm, and is automatically sent out after polishing is completed. The entire polishing process does not require frequent manual intervention, which reduces the error and labor intensity of manual operation, improves the stability and consistency of the production process, ensures the stability of product quality, and also improves the production management level and production efficiency of the enterprise.

4. High-precision polishing

With precise mechanical structure and advanced control system, Dry High-Speed Automatic Polishing Machine can accurately control key parameters such as contact pressure between the polishing head and the workpiece and polishing time. This significantly improves the polishing accuracy of the workpiece surface, achieves good surface finish and flatness, and meets the strict requirements of different metal workpieces for surface quality. Whether it is high-precision mechanical parts or metal products with high requirements for surface aesthetics, high-quality polishing effects can be obtained through this equipment.

5. Wide applicability

Dry High-Speed Automatic Polishing Machine can adapt to the polishing needs of metal workpieces of various shapes by adjusting the shape, position and motion trajectory of the polishing head. Whether it is a flat, cylindrical or complex curved metal workpiece, such as metal crafts, it can be effectively polished. This wide range of applicability makes the equipment highly versatile in the metal processing industry, able to meet the needs of different customers for surface treatment of different types of metal workpieces, and provide enterprises with flexible production solutions.

6. Reliable core components

The core components of the equipment include PLC and motors, which are made of high-quality materials and advanced manufacturing processes to ensure the stable operation and long-term reliability of the equipment. The PLC system can accurately control the automated operation process of the equipment, while the efficient and stable motor provides strong power for the high-speed rotation of the polishing head. The perfect combination of the two enables the Dry High-Speed Automatic Polishing Machine to always maintain good performance during long-term and high-intensity production operations, providing a strong guarantee for the continuous production of enterprises.

7. High power and high power

The Dry High-Speed Automatic Polishing Machine is equipped with a high-power motor of 18.5 kilowatts, which can provide sufficient power support for the polishing head. This high-power configuration ensures that the polishing head can generate sufficient polishing force during high-speed rotation, and even in the face of harder or thicker metal workpieces, it can ensure the uniformity and consistency of the polishing effect, meet the polishing needs of different metal materials and workpiece sizes, and enable the equipment to perform excellent performance in various complex polishing tasks.

8. Sturdy and durable

The weight of the equipment reaches 3000 kg, and the overall structure is sturdy and stable. This heavy-duty design can not only ensure the stability of the equipment during operation and reduce the impact of vibration on polishing accuracy, but also enable it to operate stably for a long time in harsh industrial production environments and have a long service life. At the same time, the sturdy body structure also provides a reliable physical basis for the high-precision polishing and automated operation of the equipment, ensuring that the Dry High-Speed Automatic Polishing Machine always maintains good performance and working condition during long-term use.

9. Customized service

The equipment provides customized service and can be designed and manufactured according to the specific needs of customers. For example, customers can customize the equipment specifications, polishing head type, degree of automation, etc. according to the size, shape, material and production requirements of their own workpieces. This customized service meets the diverse needs of different industries and enterprises, allowing the dry high-speed automatic polishing machine to be better integrated into the customer's production line, maximize production benefits, and create more value for customers.

| Origin: | Guangdong, China |

| Condition: | Brand new |

| Video factory inspection: | Provided |

| Mechanical test report: | Provided |

| Marketing type: | General product |

| Core component warranty: | 1 year |

| Core components: | PLC, motor |

| Power (kW) | 4.4 |

| Weight (KG) | 600 |

| Main selling point | Easy to operate |

| Warranty | 1 year |

| Showroom location | No |

| Brand | Zhuosheng |

| Model | ZS-SP-420 |

| Power supply voltage | 220V |

| No-load speed | 2800r/min |

| Speed | 2800r/min |

| Rated input power | 4.0KW |

| Speed change | stepless speed change |

| Equipment volume | 800*1200*1850(mm) |

| Maximum specifications of consumables | 8 inches, 12 inches, center hole 25 inches |

| After-sales service provided: | video technical support |

1. Non-standard customization: meet personalized technical requirements.

2. Samples and drawings: professional R&D team design.

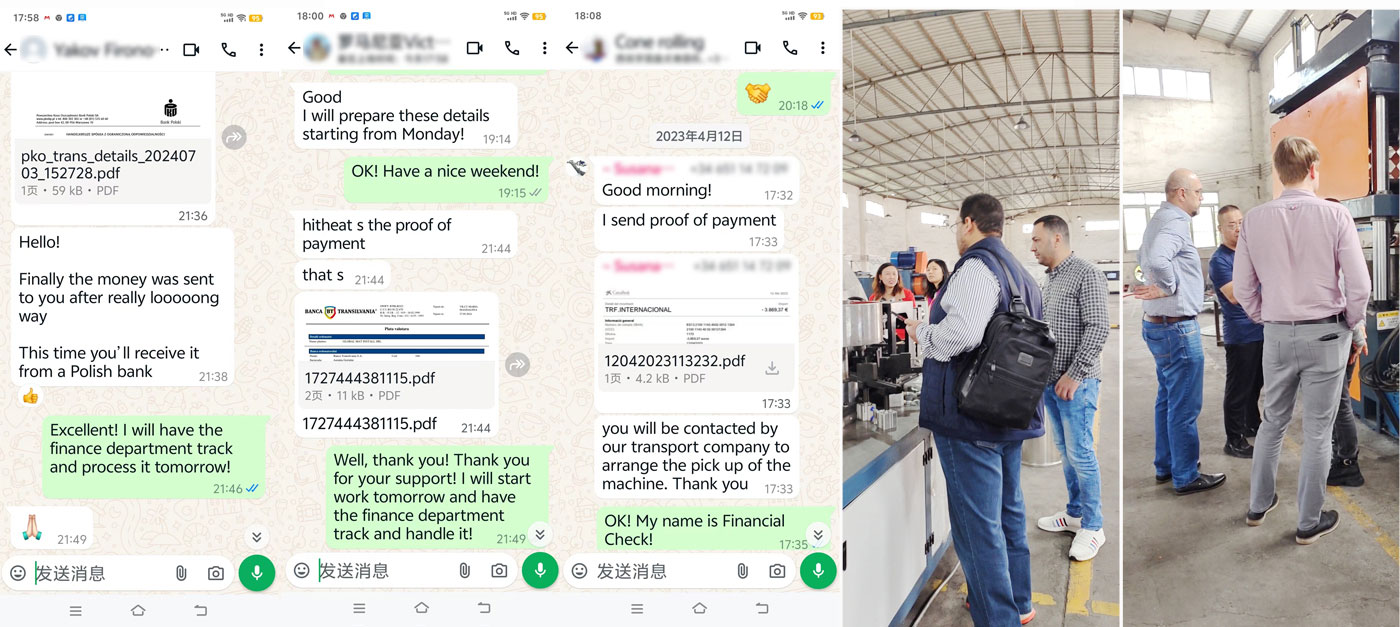

3. Flexible payment: T/T, LC, international bank.

4. Video factory inspection: can be scheduled.

5.Experienced professional sales service team.

6. Visual production process.

1. Provide circuit diagrams, maintenance manuals,full-course teaching videos and other materials required.

2. Full-time after-sales service, cooperate with customers to inspect, install and test.

3. Quick response: respond within 24 hours if there are any problems with the customers use.

1. Aerospace

In the aerospace industry, the surface quality of metal parts is crucial to flight safety. The Dry High-Speed Automatic Polishing Machine can be used to polish key parts such as aircraft engine blades and wing frames. These parts are usually complex in shape and require extremely high precision. With its high-precision polishing ability and adaptability to complex curved surfaces, the equipment can polish the surface of the parts to a finish that meets strict standards, improve the aerodynamic performance and corrosion resistance of the parts, and ensure the safe and reliable operation of the aircraft.

2. Automobile Manufacturing Industry

In automobile production, metal parts of the body, engine cylinders, etc. require good surface finish to ensure appearance quality and performance. The Dry High-Speed Automatic Polishing Machine can be used for polishing and grinding of automobile parts, such as polishing of automobile wheels. The shapes of wheels are diverse and the surface is required to be smooth. The equipment can quickly and evenly polish the surface of the wheel, remove defects such as burrs and scratches generated during casting or processing, and improve the appearance quality of the wheel. At the same time, it also helps to improve the wear resistance and corrosion resistance of the wheel, extend its service life, and provide protection for the beauty and performance of the car.

3. Mechanical processing industry

Mechanical processing enterprises produce various mechanical parts, such as gears, shaft parts, etc. Dry High-Speed Automatic Polishing Machine can be used for surface polishing of these parts to remove knife marks and burrs generated during the processing process. For example, after the gear is processed, the gear surface is polished by the equipment, which can improve the meshing performance of the gear, reduce noise, and enhance the transmission efficiency and service life of the gear. Its efficient and automated polishing process can be well integrated into the mechanical processing production line, improve overall production efficiency, and ensure the consistency of product quality.

4. Hardware products industry

The surface quality of metal products such as tools and locks directly affects the market competitiveness of the products. Dry High-Speed Automatic Polishing Machine can finely polish hardware products to achieve a mirror effect or the required specific finish. For some irregularly shaped hardware tools, the equipment can perform adaptive polishing by adjusting the motion trajectory of the polishing head, improve the appearance and feel of the hardware products, enhance the market appeal of the products, and meet consumers' high requirements for the surface quality of hardware products.

5. Electronic and electrical industry

Metal shells, heat sinks and other parts in electronic and electrical products require good surface finish to ensure the appearance and heat dissipation performance of the products. Dry High-Speed Automatic Polishing Machine can be used for polishing these parts, such as polishing the metal shell of mobile phones. The dimensional accuracy of mobile phone shells is high, and the surface needs to be smooth and delicate. The equipment can quickly remove the processing marks on the shell surface to achieve the ideal finish, while avoiding the pollution and damage to electronic components caused by liquid polishing, ensuring the quality and performance of electronic and electrical products.

6. Medical device industry

Medical devices such as surgical instruments and metal parts implanted in the body have extremely strict requirements on surface quality to prevent bacterial growth and reduce adverse reactions of human tissues. Dry High-Speed Automatic Polishing Machine can finely polish these medical devices to make their surfaces highly smooth and reduce surface roughness. For example, polishing medical stainless steel surgical blades can improve the sharpness and surface finish of the blades, reduce tissue damage during surgery, and also help clean and disinfect medical devices to ensure medical safety.

High-speed rotary polishing:

The polishing head inside the equipment runs at a high speed driven by the motor, and the speed is usually high, which can quickly remove the defects on the surface of the metal workpiece. For example, its rotation speed may reach thousands of revolutions per minute. When the workpiece contacts the polishing head, under the action of friction, the tiny protrusions and oxide layers on the surface of the workpiece are gradually smoothed.

Automated process:

It has an automated loading, polishing and unloading system. The workpiece is automatically transported to the polishing area through a conveyor belt or a robotic arm, and then automatically sent out after polishing. The whole process does not require frequent manual intervention, which greatly improves work efficiency.

We are grateful for your support and trust along the way. We are honored by your cooperation every time, and we will live up to your trust and provide you with a more excellent experience.

We can also help you with all your equipment packaging needs. Whether you need split packaging, certified materials or general packaging advice, our team of experts can help you. We understand that every business is different, so we tailor our services to your needs. Our goal is to make your life easier by meeting all your packaging needs so that you can focus on running your business.

As a professional mechanical equipment manufacturer, our company is a private technology innovation enterprise integrating independent research and development, design and manufacturing, installation and commissioning, and training.

Our R&D team has 10 people, whose members cover multiple professional fields such as mechanical engineering, electronic information, and materials science, and have the ability to deal with different technical problems.

Our equipment is widely used in aerospace, energy, ventilation,hardware and furniture, tableware, medicine, electricity, packaging,construction,automobile and other industries and fields.