Automatic hydraulic five-axis CNC four-roller plate rolling machine

This equipment is one of the flagship products of Jiangmen Zhuosheng Machinery Co., Ltd., specially designed and manufactured for rolling cylindrical workpieces of metal materials such as stainless steel, galvanized plates, cold plates, etc. It also has a number of national related patents. Long-term production and processing have enabled our company to accumulate rich technical experience, making our equipment at a relatively advanced level. The machine tools produced by our company have stable performance and easy operation. The CNC five-axis plate rolling machine produced by our company has the advantages of good rolling roundness, no need for separate pre-bending, small rolling straight edge, and one-button start of rolling and forming.

Equipment features:

1:Hydraulic drive is highly efficient and energy-saving

Full hydraulic drive, high efficiency and energy saving (drive power is equivalent to 60% of the traditional one), safer and more reliable than the traditional three-roller plate rolling machine during rolling;

2:Permanent lubrication technology

Permanent lubrication technology (no need to add oil during the life of the bearing);

3:Adjustable clamping pressure

Adjustable clamping pressure (no slippage, productivity is 50%-80% higher than the three-roller plate rolling machine), the clamping force between the upper and lower rollers on the plate can be adjusted by the hydraulic station pressure regulating valve to adjust the corresponding required pressure when rolling plates of different thicknesses and widths;

4:Special pre-bending function

The minimum cylinder that can be rolled can reach 1.3 times the diameter of the upper roller, and the straight edge length of the pre-bent end of the rolled plate is smaller than that of other types of plate rolling machines.

| Upper roller diameter: | Φ 170 ㎜ |

| Lower roller diameter: | Φ 160 ㎜ |

| Side roller diameter: | Φ 140 ㎜ |

| Maximum rolled plate thickness: | 6mm |

| Maximum pre-bent plate thickness: | 4.8mm |

| Maximum rolled plate width: | 1500mm |

| Working roller drive form: | upper roller hydraulic motor drive |

| Sheet yield limit: | ≤245Mpa |

| Rolling speed: | about 6m/min |

| Pre-bending remaining straight edge: | ≤1.5 plate thickness |

| Minimum roll diameter: | about Φ250mm |

| Total equipment power: | 5.5KW |

| Power supply voltage: | AC 380V three-phase four-wire |

| Control mode: | PLC/CNC |

| Power mode: | hydraulic |

1. Non-standard customization: meet personalized technical requirements.

2. Samples and drawings: professional R&D team design.

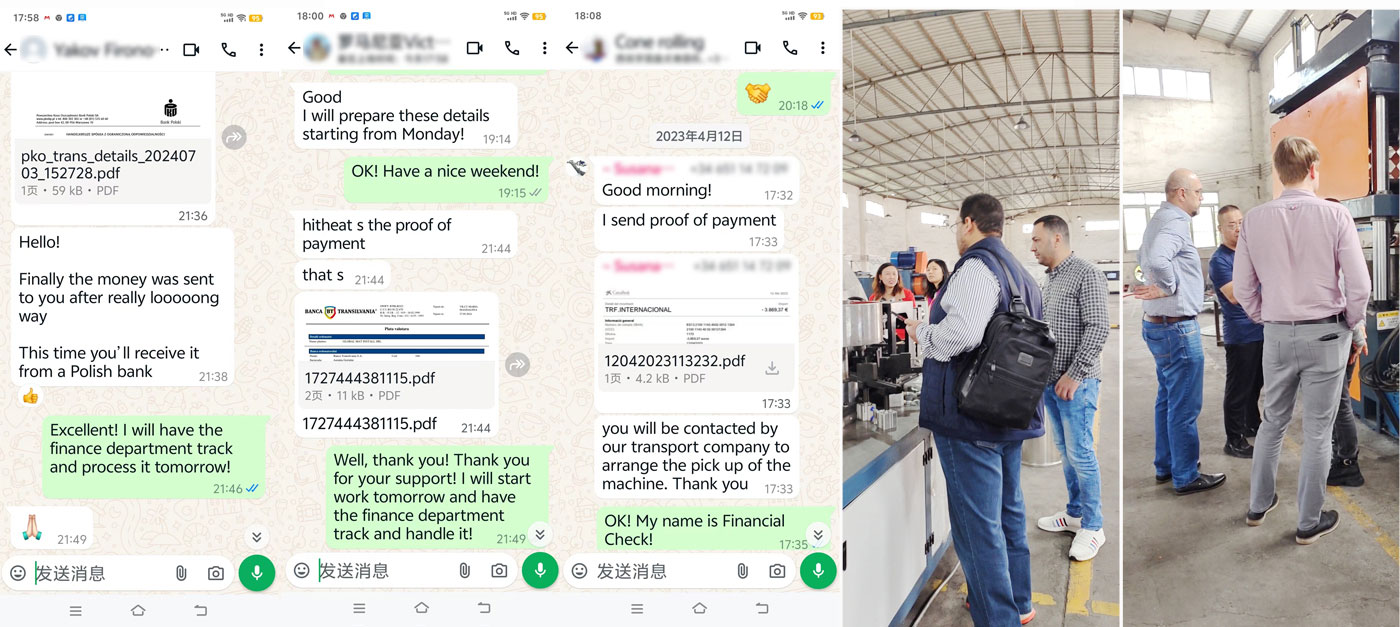

3. Flexible payment: T/T, LC, international bank.

4. Video factory inspection: can be scheduled.

5.Experienced professional sales service team.

6. Visual production process.

1. Provide circuit diagrams, maintenance manuals,full-course teaching videos and other materials required.

2. Full-time after-sales service, cooperate with customers to inspect, install and test.

3. Quick response: respond within 24 hours if there are any problems with the customers use.

We are grateful for your support and trust along the way. We are honored by your cooperation every time, and we will live up to your trust and provide you with a more excellent experience.

We can also help you with all your equipment packaging needs. Whether you need split packaging, certified materials or general packaging advice, our team of experts can help you. We understand that every business is different, so we tailor our services to your needs. Our goal is to make your life easier by meeting all your packaging needs so that you can focus on running your business.

As a professional mechanical equipment manufacturer, our company is a private technology innovation enterprise integrating independent research and development, design and manufacturing, installation and commissioning, and training.

Our R&D team has 10 people, whose members cover multiple professional fields such as mechanical engineering, electronic information, and materials science, and have the ability to deal with different technical problems.

Our equipment is widely used in aerospace, energy, ventilation,hardware and furniture, tableware, medicine, electricity, packaging,construction,automobile and other industries and fields.