A CNC spinning machine is an advanced device that utilizes numerical control technology to control the spinning process. It utilizes computer programs to control the machine's motion and machining process, achieving high-precision and efficient sheet metal processing. CNC spinning machines are capable of processing complex metal parts, such as cylinders, cones, and parabolas. Its core advantage lies in its ability to precisely control machining parameters, such as spindle speed and feed rate, ensuring consistent and stable machining quality. The CNC spinning machine's high degree of automation reduces manual intervention, improving production efficiency and machining accuracy.

1. Sturdy Construction:

The Hydraulic Automatic CNC Spinning Machine utilizes high-strength steel for its construction, offering exceptional stability and impact resistance, providing a solid foundation for high-precision machining. The optimized construction ensures high precision even under extended, high-load operation. This robust design not only extends the machine's service life but also reduces machining errors caused by deformation.

2. Precision Wheel System:

The wheel, a core component of the CNC Spinning Machine, undergoes precision machining and rigorous testing to ensure stable pressure application and precise shaping during machining. The wheel's material selection and surface treatment meet industry standards, enabling it to withstand high machining loads while maintaining a smooth and precise surface finish. By precisely controlling the wheel's motion trajectory and pressure distribution, the machine can complete the machining of complex metal parts to meet custom requirements.

3. Advanced CNC System:

Equipped with a renowned brand CNC system, it boasts powerful computing power and stable performance, enabling precise control of parameters such as spindle speed and wheel feed rate to ensure machining accuracy and consistency. This CNC system supports multiple programming languages and operating modes, allowing users to flexibly configure it based on specific processing requirements. The system also features fault diagnosis and alarm functions, enabling timely detection and resolution of abnormalities during processing, improving equipment reliability and operational efficiency.

4. Efficient Transmission System:

The Hydraulic Automatic CNC Spinning Machine utilizes high-quality transmission components, such as precision ball screws, which offer high transmission accuracy and minimal thermal deformation, ensuring long-term, stable operation. The optimized transmission system design reduces energy loss, improves transmission efficiency, and reduces noise and vibration during operation. This efficient transmission system not only enhances processing accuracy but also extends its service life and reduces maintenance costs.

5. Automatic Lubrication System:

Equipped with an AC 220V 25W1 automatic lubrication system, it automatically lubricates key components, reducing wear and extending equipment life. The automatic lubrication system automatically adjusts lubrication frequency and quantity based on the machine's operating status, ensuring adequate lubrication under varying operating conditions. This intelligent lubrication system not only improves operational efficiency but also reduces equipment failures caused by insufficient lubrication.

6. Precise Parameter Control:

The Hydraulic Automatic CNC Spinning Machine has a maximum spinning product diameter of 400 mm (sheet diameter), a light-duty machining capacity, and a maximum workpiece weight of 40.8 kg. The spindle motor has a power of 5.5 kW, a spindle speed range of 100-2500 rpm, an X-axis travel of 400 mm, and a Z-axis travel of 210 mm. Positioning accuracy is ±0.02 mm, repeatability is ±0.02 mm, and the machine supports 6+6 tool positions. These precise parameter controls ensure high precision and efficiency during machining, meeting the customized needs of diverse customers.

7. Stable Power Supply:

The machine utilizes an AC 380V three-phase, four-wire power supply, ensuring a stable and reliable power supply during operation. A stable power supply is essential for normal operation, preventing equipment failure and machining errors caused by voltage fluctuations. The machine is also equipped with overload and short-circuit protection devices.

8. User-Friendly Design:

The CNC Spinning Machine utilizes a PLC touchscreen control system, offering a simple, intuitive user interface and ease of use. Measuring 2300 x 1200 x 1700 mm and weighing 2500 kg, the machine is suitable for installation and use in most factory workshops. It also comes with a mechanical inspection report and video factory inspection service, providing comprehensive quality assurance.

| Power supply type: | AC 380V three-phase four-wire |

| Maximum spinning product diameter (mm): | 400 (sheet diameter) |

| Processing capacity: | light |

| Maximum workpiece weight (kg): | 40.8 |

| Spindle motor power (kW): | 5.5 |

| Number of spindles: | single axis |

| Spindle speed: | 100-2500 rpm |

| Stroke (X axis) (mm): | 400 mm |

| Stroke (Z axis) (mm): | 210 mm |

| Positioning accuracy (mm): | ±0.02 |

| Repeat accuracy (X/Y/Z) (mm): | ±0.02 |

| Origin: | Guangdong, China |

| Installable tool positions: | 6+6 |

| Weight (KG): | 2500 |

| Warranty: | 1 year |

| Mechanical inspection report: | provided |

| Video factory inspection: | provided |

| Core component warranty: | 1 year |

| Screw width (mm): | 30 mm |

| Feed speed: | 5 meters/minute |

| Dimensions (length*width*height): | 2300x1200x1700 (mm) |

| Brand: | Zhuosheng |

| Model number: | ZS-XY-400 |

| Automatic oiling system: | AC 220V 25W1 |

| CNC system: | GuGe |

| Main selling point: | Multi-function |

| Type: | Cold bending machine |

| Control method: | PLC touch screen CNC |

1. Non-standard customization: meet personalized technical requirements.

2. Samples and drawings: professional R&D team design.

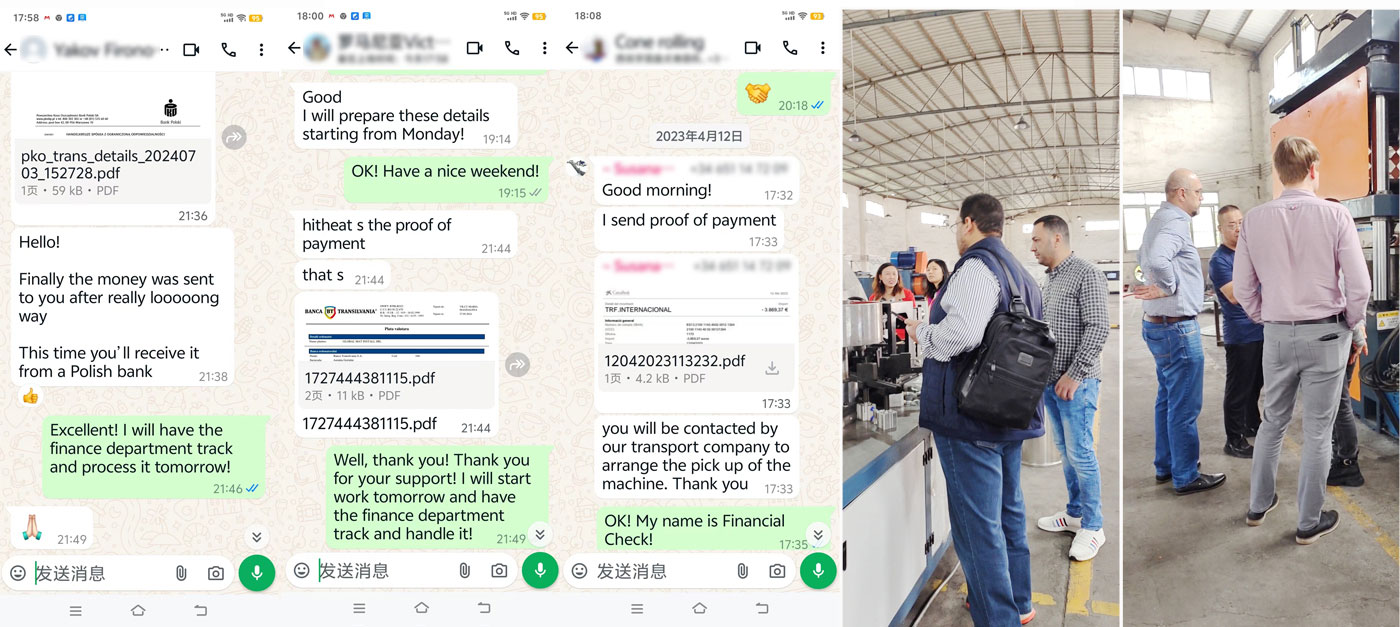

3. Flexible payment: T/T, LC, international bank.

4. Video factory inspection: can be scheduled.

5.Experienced professional sales service team.

6. Visual production process.

1. Provide circuit diagrams, maintenance manuals,full-course teaching videos and other materials required.

2. Full-time after-sales service, cooperate with customers to inspect, install and test.

3. Quick response: respond within 24 hours if there are any problems with the customers use.

1. Aerospace:

In the aerospace sector, Hydraulic Automatic CNC Spinning Machines are used to manufacture complex metal parts such as aircraft fuselages and engine components. Their high-precision machining capabilities meet the industry's stringent requirements for components, ensuring their strength and reliability. By precisely controlling machining parameters, this equipment enables high-precision spin forming, meeting the specialized needs of the aerospace industry.

2. Automotive:

In the automotive industry, CNC Spinning Machines are used to produce components such as wheels and body parts. Their high degree of automation improves production efficiency while ensuring consistent and stable machining quality. By optimizing machining processes, this equipment reduces material waste, lowers production costs, and enhances enterprise competitiveness.

3. Home Appliance Manufacturing: In the home appliance industry, CNC Spinning Machines are used to manufacture components such as washing machine drums and air conditioner housings. Their precise machining capabilities ensure dimensional accuracy and surface quality, meeting the industry's requirements for both appearance and performance.

4. Mechanical Processing Industry:

In the mechanical processing industry, CNC spinning machines are used to manufacture various mechanical components, such as gears and shafts. Their powerful machining capabilities and high-precision control meet the diverse needs of the machining industry, improving processing efficiency and product quality.

5. Hardware Industry:

In the hardware industry, CNC spinning machines are used to produce various hardware products, such as lamps and decorative parts. Their high-precision machining capabilities ensure product appearance quality and dimensional accuracy, meeting the hardware industry's requirements for both appearance and performance.

6. Electronic Equipment Industry:

In the electronic equipment industry, CNC spinning machines are used to manufacture components such as electronic equipment casings and heat sinks. Their high-precision machining capabilities ensure component dimensional accuracy and appearance quality, meeting the electronic equipment industry's requirements for both appearance and performance.

We are grateful for your support and trust along the way. We are honored by your cooperation every time, and we will live up to your trust and provide you with a more excellent experience.

We can also help you with all your equipment packaging needs. Whether you need split packaging, certified materials or general packaging advice, our team of experts can help you. We understand that every business is different, so we tailor our services to your needs. Our goal is to make your life easier by meeting all your packaging needs so that you can focus on running your business.

As a professional mechanical equipment manufacturer, our company is a private technology innovation enterprise integrating independent research and development, design and manufacturing, installation and commissioning, and training.

Our R&D team has 10 people, whose members cover multiple professional fields such as mechanical engineering, electronic information, and materials science, and have the ability to deal with different technical problems.

Our equipment is widely used in aerospace, energy, ventilation,hardware and furniture, tableware, medicine, electricity, packaging,construction,automobile and other industries and fields.