The CNC spinning machine for mixing barrels is an advanced metal processing equipment specially used for high-precision spinning of mixing barrels and other similar containers. Mixing Barrel Cnc Spinning Forming Lathe combines CNC technology with traditional spinning process to bring efficient, accurate and reliable solutions to the production of mixing barrels.

Mixing Barrel Cnc Spinning Forming Lathe:

1. With mature CAD drawing programming software functions, the motion trajectory of the spinning wheel can be straight lines, arcs, multi-arc connecting lines and combined curves, etc. And input into the computer for standardized programming of passes.

2. The operator can input process parameters and spinning passes through the keyboard and operation panel, and can edit, store and call them at will.

3. It has the function of "copying" the core mold contour protection, that is, when adjusting the process and recording and returning the teaching, the spinning wheel will not collide with the core mold.

4. The machine tool can pause the feed speed and spindle speed in the automatic program. It is equipped with travel limit protection, software and hardware limit protection in the control system, fault detection and alarm functions.

5. Automatically detect faults of each unit when starting up, automatic diagnosis and overload protection, etc.

6. According to the user's requirements, various special shapes of parts can be spun to ensure that the workpiece surface, diameter, thinning rate and other related dimensions meet the requirements.

7. The same machine tool can complete trimming, flanging, curling, shrinking, rolling and other functions.

1. CNC System

Using advanced CNC technology, precise motion control and parameter adjustment can be achieved. You can easily set various spinning process parameters, such as rotation speed, feed speed, spinning force, etc. through programming to meet the processing needs of mixing barrels of different specifications.

It has a friendly human-machine interface and is easy to operate. Even operators without rich experience can quickly get started.

Powerful programming functions can realize the processing of mixing barrels with complex shapes and improve the versatility of the equipment.

2. Powerful Spinning Mechanism

Equipped with high-power motors and high-precision transmission systems to ensure strong power and stable operation during the spinning process. It can efficiently spin metal sheets of various thicknesses to produce mixing barrels with uniform wall thickness and regular shape.

Unique spinning mold design can be customized according to the size and shape of the mixing barrel to ensure processing accuracy and surface quality.

Use high-quality materials and advanced manufacturing technology to improve the durability and reliability of the spinning mechanism.

3. High degree of automation

The whole process of automatic loading, spinning processing and unloading can be automated, which greatly improves production efficiency and reduces the labor intensity and errors of manual operation.

Equipped with an automatic detection system to monitor various parameters in the processing process, such as pressure, temperature, size, etc. in real time to ensure the stability of product quality.

It has a fault self-diagnosis function, which can detect and solve equipment failures in time and improve the reliability of the equipment.

4. Energy saving and environmental protection

Adopt high-efficiency and energy-saving motors and transmission systems to reduce energy consumption. At the same time, less waste is generated during the spinning process, which meets environmental protection requirements.

Optimized processing technology reduces noise and vibration during processing and improves the working environment.

5. High-precision processing

Adopt high-precision sensors and control systems to ensure the dimensional accuracy and shape accuracy of the mixing barrel. The processing accuracy can reach ±0.05mm, which meets the needs of the high-end market.

Equipped with a precise positioning system to ensure the consistent processing accuracy of each part of the mixing barrel and improve the overall quality of the product.

6. Versatility

In addition to processing mixing barrels, other metal containers of similar shapes, such as storage tanks, reactors, etc., can also be processed to improve the utilization rate of equipment.

Customized processing of special shapes and sizes can be carried out according to customer needs to meet the special needs of different industries.

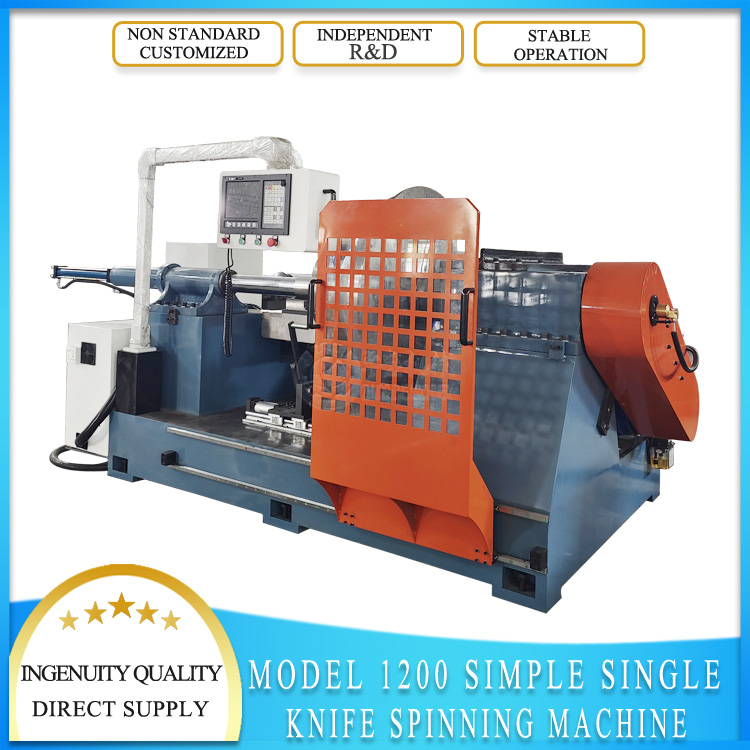

| Power supply type: | AC 380V three-phase four-wire |

| Maximum spinning product diameter (mm): | 1200 (sheet diameter) |

| Processing capacity: | heavy |

| Maximum workpiece weight (kg): | 550 |

| Spindle motor power (kW): | 23 |

| Number of spindles: | single axis |

| Spindle speed: | 10-750 rpm |

| Stroke (X axis) (mm): | 800 mm |

| Stroke (Z axis) (mm): | 610 mm |

| Positioning accuracy (mm): | ±0.02 |

| Repeat accuracy (X/Y/Z) (mm): | ±0.01 |

| Origin: | Guangdong, China |

| Installable tool positions: | 6+6 |

| Weight (KG): | 7600 |

| Warranty: | 1 year |

| Mechanical inspection report: | provided |

| Video factory inspection: | provided |

| Core component warranty: | 1 year |

| Screw width (mm): | 45 mm |

| Feed speed: | 5 meters/minute |

| Dimensions (length*width*height): | 3200x2000x1800 (mm) |

| Brand: | Zhuosheng |

| Model number: | ZS-XY-1200 |

| Automatic oiling system: | AC 220V 25W1 |

| CNC system: | Diens/Gugo |

| Main selling point: | Multi-function |

| Type: | Cold bending machine |

| Control method: | PLC touch screen CNC |

1. Non-standard customization: meet personalized technical requirements.

2. Samples and drawings: professional R&D team design.

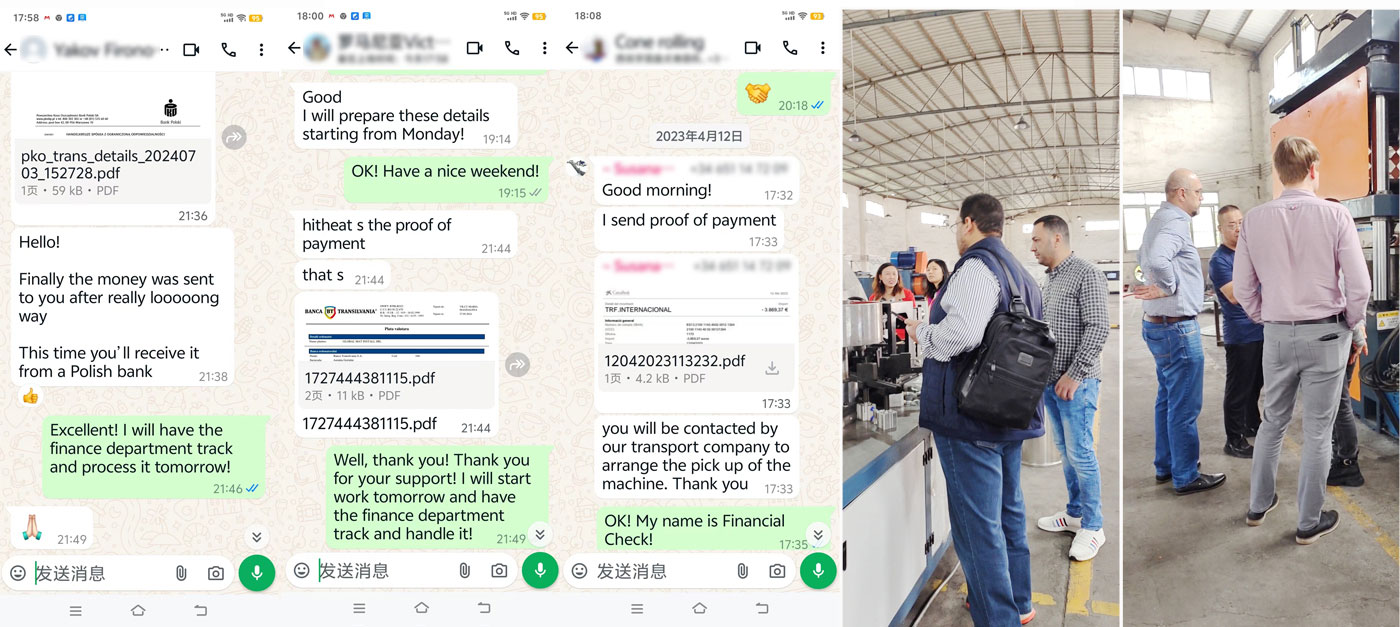

3. Flexible payment: T/T, LC, international bank.

4. Video factory inspection: can be scheduled.

5.Experienced professional sales service team.

6. Visual production process.

1. Provide circuit diagrams, maintenance manuals,full-course teaching videos and other materials required.

2. Full-time after-sales service, cooperate with customers to inspect, install and test.

3. Quick response: respond within 24 hours if there are any problems with the customers use.

Application:

CNC spinning machines for mixing barrels are widely used in the production of mixing barrels in the chemical, food, pharmaceutical and other industries. It is suitable for processing metal sheets of various materials, such as stainless steel, carbon steel, aluminum alloy, etc. Whether it is a small laboratory mixing barrel or a large industrial mixing barrel, high-quality processing can be achieved through this equipment.

Advantages Summary:

1. High-precision processing: ensure the dimensional accuracy and shape accuracy of the mixing barrel and improve product quality.

2. Efficient production: high degree of automation, greatly shortening the production cycle and improving production efficiency.

3. Flexible customization: customized processing can be carried out according to the different needs of customers to meet diverse market needs.

4. Energy saving and environmental protection: reduce energy consumption, reduce waste generation, and meet the requirements of sustainable development.

5. Versatility: It can process metal containers of various shapes and sizes, improving the utilization rate of the equipment.

In short, the mixing barrel CNC spinning machine is a metal processing equipment with advanced technology and excellent performance, which provides a reliable guarantee for the production of mixing barrels.

We are grateful for your support and trust along the way. We are honored by your cooperation every time, and we will live up to your trust and provide you with a more excellent experience.

We can also help you with all your equipment packaging needs. Whether you need split packaging, certified materials or general packaging advice, our team of experts can help you. We understand that every business is different, so we tailor our services to your needs. Our goal is to make your life easier by meeting all your packaging needs so that you can focus on running your business.

As a professional mechanical equipment manufacturer, our company is a private technology innovation enterprise integrating independent research and development, design and manufacturing, installation and commissioning, and training.

Our R&D team has 10 people, whose members cover multiple professional fields such as mechanical engineering, electronic information, and materials science, and have the ability to deal with different technical problems.

Our equipment is widely used in aerospace, energy, ventilation,hardware and furniture, tableware, medicine, electricity, packaging,construction,automobile and other industries and fields.

Q: When shipping, what kind of packing?

A: We use standard export packing.

Q: What are your delivery terms?

A: EXW, FOB, CFR, CIF.

Q: What's your delivery time?

A: Generally speaking, it takes 30 to 60 days after receiving your advance payment. The specific delivery time depends on the item and quantity of your order.

Q: Can you make it as required?

A: Yes, we can produce according to your samples or technical drawings. We can make molds and fixtures.

Q: Do you have professional engineers?

A: Yes.we have professional engineers and designers.

Q: Can you provide customzied machines?

A:Yes, we can design and manufacture according to your specific requirements.